Riven’s new Warp-Adapted Model for improved AM accuracy

December 1, 2021

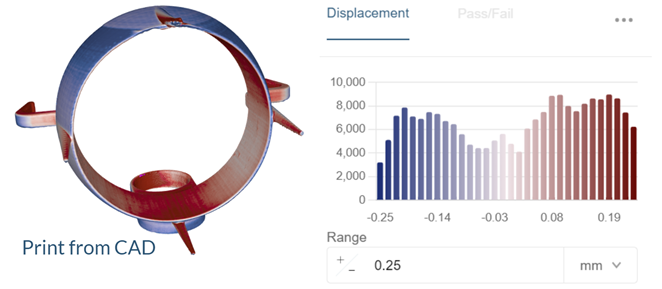

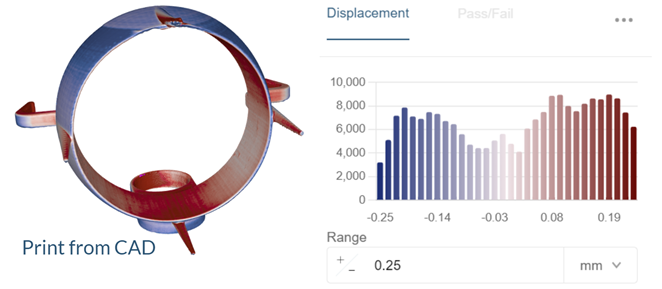

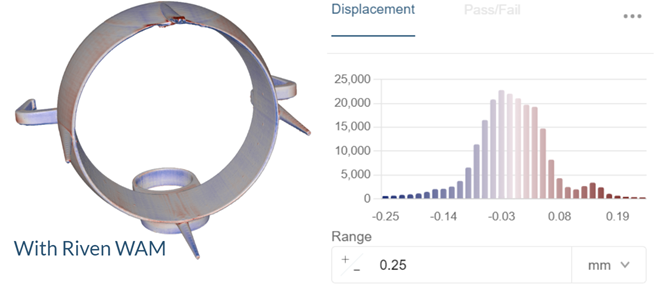

Riven, Berkeley, California, USA, has developed Warp-Adapted-Model (WAM™) capability that is said to enable higher accuracy in Additive Manufacturing part production. WAM uses full-part 3D data from an initial part to identify errors and produces a new corrected model in minutes that eliminates warp and is up to ten times more accurate when additively manufactured. Riven customers are said to already be using WAM to enable more accurate production.

WAM capability has been tested extensively and is said to have shown improvement across a wide variety of Additive Manufacturing technologies, including the Material Extrusion (MEX) process Fused Filament Fabrication (FFF), Laser Beam Powder Bed Fusion (PBF-LB) and metal Binder Jetting (BJT). The technology reportedly improved accuracy for every build, including proactively correcting errors on legacy equipment.

Nate Higgins, president of FreeFORM Technologies, a service bureau working in end-use metal BJT, stated, “Riven’s WAM is a unique and powerful capability that enables us to deliver production parts with tighter tolerances and saves weeks by eliminating process iterations. This further demonstrates Riven’s value in speeding up product acceptance and improving the experience of our mid-size and Fortune 500 customers.”

WAM is said to work for AM technologies without the need for detailed knowledge of the specific machine or material parameters. The technology is reputed to be complementary to simulation-based approaches and can be used alone or in combination to correct errors related to environmental conditions or imperfect simulation input.

In a comprehensive FFF trial, average build errors were said to be reduced by over 2.8 times where the accuracy score improved from 80% to 93% (with errors are defined as areas with deviation over 0.25 mm). Trials were conducted with three different part types and in three different materials.

Riven is also pre-release testing PWAM™, a predictive, machine-learning driven version of the technology which creates pre-adjusted models automatically and is anticipated to deliver even greater economies of scale while minimising production of scrap parts.

“Our objective is to accelerate the entire AM industry by enabling systematic ramp-up of production AM parts,” added James Page, founder and CTO of Riven. “Parts printed with Riven’s WAM and forthcoming PWAM will be within spec and can be shipped – whereas initial parts printed from CAD are frequently out of tolerance and cannot be shipped to customers. WAM saves resources, reduces waste, and improves customer service.”

Those interested in learning more about WAM can register for Riven’s webinar, scheduled to take place December 8, 2021.