Ricoh expands Binder Jetting material line-up with 6000 series aluminium

February 14, 2023

Ricoh Company, Ltd, headquartered in Tokyo, Japan, is expanding its aluminium Binder Jetting (BJT) material range to include 6000 series aluminium alloy (AlSiMg). In conventional manufacturing, the 6000 series is a commonly used class of aluminium alloy, bringing high strength and corrosion-resistant properties to a wide range of applications.

The 6000 series aluminium alloys are, however, more susceptible to oxidation and less tolerant of impurities, making them some of the most difficult to sinter, explains Ricoh.

In 2020 the company released a 4000 series aluminium (AlSi) that, thanks to the adoption of a liquid-phase sintering technology, made the Binder Jetting of this material possible. In the development of the 6000 series, Ricoh partnered with the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM, Bremen, Germany, and again made use of the liquid-phase sintering process.

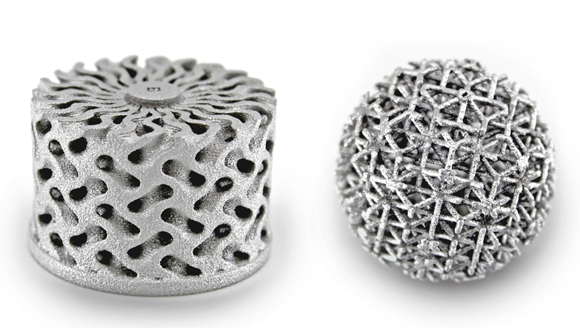

When sintering the 6000 series, Ricoh precisely controls the gases in the furnace and uses a highly degradable binder with an optimised debinding process. These technological developments have now made it possible to use Binder Jetting to produce complex 6000 series parts, such as those seen in Fig. 1.

Properties of sintered 6000 series aluminium parts

In the Binder Jetting process, a droplet of binder is selectively deposited on a powder bed, layer by layer, to fabricate a green body. This green part then undergoes a debind and sinter process, densifying the green body to obtain the sintered part. However, the Binder Jetting of aluminium has proved problematic because surface oxide hinders densification in the sintering stage.

Following the development of Ricoh’s 6000 series aluminium, results have shown that the relative density of the sintered 6000 aluminium parts produced exceeds 97%.

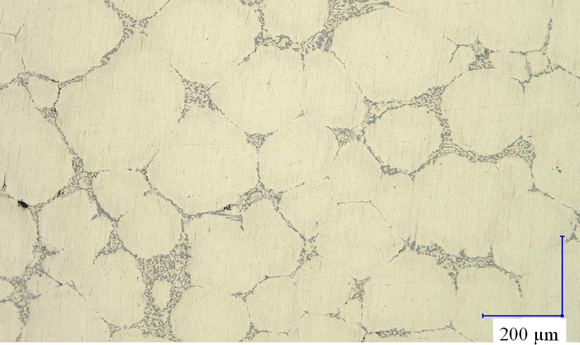

X-ray computed tomography (Fig. 2) of the sintered sample shows that there are no large voids on either the surface or internally. The microstructure of the same 6000 series sample is shown in Fig. 3 under higher magnification, also indicating sufficient densification after sintering. The relative density of the observed sample was recorded as 97.9%.

Ricoh explains that properties important for aluminium applications, such as tensile strength and thermal conductivity, are equivalent to those of conventional methods. The tensile strength of the sample was reported to be approximately 250 MPa after T6 heat treatment, a common heat treatment for 6000 series aluminium. The thermal conductivity, measured by the laser flash method, was also recorded at 180 W/mK which is equivalent to 6000 series aluminium castings.

Further collaboration

Ricoh states that its 6000 series is ideal for heat exchanger and lightweight structural components, as well as other applications. The company plans to focus on collaborations with customers, along with further development of the new technology.

“We believe that dialogue and co-creation with our customers are extremely important, as is technology development,” stated Takafumi Sasaki, Manager of European AM department, Ricoh Futures BU, Ricoh Company. “We aim to accelerate collaboration with technical partners and customers by utilising this newly developed technology, through the activities at the Customer Experience Centre in Telford, the UK.”

Download Metal AM magazine