Researchers use adaptive slicing to reduce Binder Jetting build time

May 26, 2023

Researchers from Ondokuz Mayıs University, Samsun, Türkiye, have published work in Rapid Prototyping Journal which focused on the use of adaptive slicing in Binder Jetting Additive Manufacturing. Slicing is an essential step for all Additive Manufacturing technologies, though this slicing is usually performed uniformly.

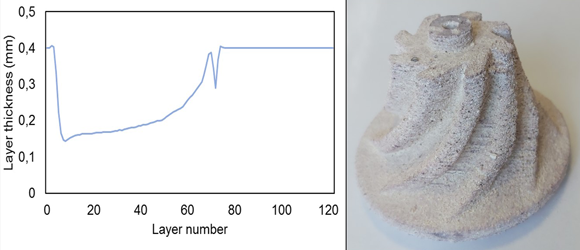

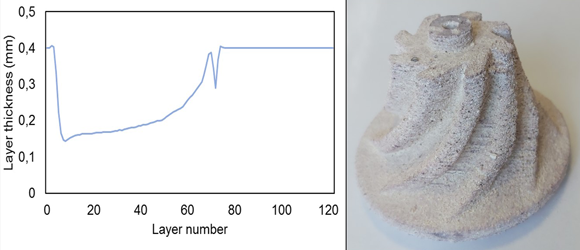

Unlike uniform slicing, layer thicknesses are variable in adaptive slicing. Adaptive slicing has been used for a long time in Fused Filament Fabrication, a form of Material Extrusion technology, but the authors claim it has not been fully explored or tested for the Binder Jetting process. The reasons for this, they suggest, is that slicing software used for Binder Jetting does not allow adaptive slicing, or that the commercial BJT machines used are unsuitable for applying adaptive slicing.

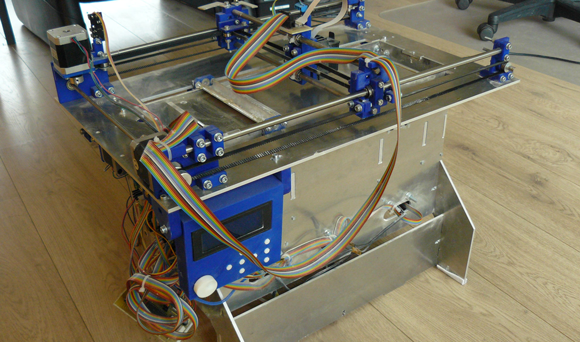

In an effort to remedy this lack of study, the Ondokuz Mayıs researchers implemented adaptive slicing using an open-source Additive Manufacturing machine (a Plan B from Ytec3D), open-source slicing software (Slic3r), and a self-developed variable binder amount algorithm (VBAA).

VBAA is an algorithm developed for the efficient use of adaptive slicing, included in the software of the open-source AM machine. A VBAA is a necessity, as, if it’s not used, the same amount of binder is sent to layers regardless of any difference in thickness. This presents an issue as if too much binder is sent to a thinner layer, the dimension expands and the surface roughness increases – if too little binder is sent, parts may break.

Samples were sintered at 1250°C for 2 h with 10°C/min heating and cooling ramp. Scanning electron microscope (SEM) analysis, surface roughness tests, and density calculations were done. According to the results obtained from the analyses, similar surface quality is achieved by using 38% fewer layers than uniform slicing.

Using adaptive slicing and their VBAA algorithm, the researchers reportedly achieved a reduction of Binder Jetting times of 40%. In addition, with the reduction of manufacturing times, the surface roughness did not increase, and there was no change in the part density. These results should be replicable in all commercial Binder Jetting machines as the published work is based on open-source software.

The researchers have applied for a patent for their work, and their patent application won a bronze medal at the ISIF 2023 8th Istanbul International Invention Fair.

The study, ‘Using adaptive slicing method and variable binder amount algorithm in binder jetting,’ is available here.

Download Metal AM magazine