Researchers show contact-free supports enhance surface quality

June 20, 2022

Turkish researchers from General Electric Aviation, Istanbul Technical University and Eskisehir Osmangazi University, have published a report discussing the development of contact-free support structures to improve Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing. The paper, “Contact-Free Support Structures for the Direct Metal Laser Melting Process”, was published in the journal Materials by Alican Çelik, Emre Tekoǧlu, Evren Yasa and Mehmet Șeref Sönmez.

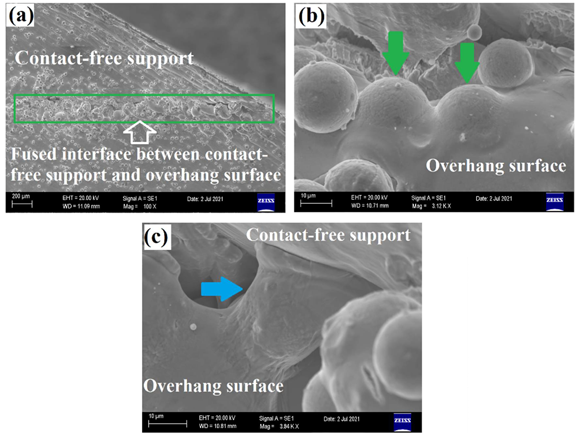

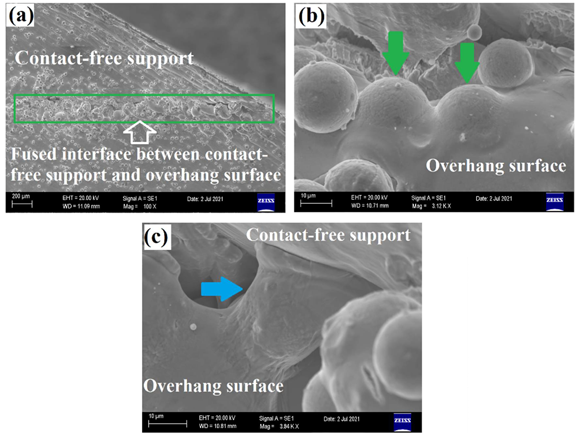

Supports are often employed to reinforce overhanging features during the build process, but their removal can have a negative impact on the part’s surface and a part’s fatigue performance. In the paper, the researchers sought to use contact-free support structures which are hoped to improve the quality of the additively manufactured parts by providing heat evacuation without touching overhanging surfaces. This step would reduce post-processing steps.

Using CrCoMo alloy powder, the researchers placed contactless supports under overhanging features with angles ranging from 15-45º and with gap differences from 100–300 μm. Using microstructural characterisations, optical microscopy and roughness measurements, the study concluded that these supports helped to reduce surface roughness at every angle, providing the correct gap distance was used: too close and the parts sinter together – too far and thermal conductivity is reduced.

The paper is available in full here.