Researchers show AM superalloy kills COVID-19 in thirty minutes

December 3, 2021

Researchers from the University of Wolverhampton and the Spanish Catholic University of Valencia’s Biomaterials and Bioengineering Lab, have published a paper, ‘3D Printed Cobalt-Chromium-Molybdenum Porous Superalloy with Superior Antiviral Activity,’ in the International Journal of Molecular Sciences.

An update to a July 2021 paper that discussed the Cu-W-Ag material’s ability to kill the coronavirus-causing SARS-CoV-2 virus within five hours, the latest journal article shows further research into additively manufacturable materials said to kill the virus within as few as thirty minutes.

The project – led by Dr Arun Arjunan, John Robinson, and Dr Ahmad Baroutaji of the University of Wolverhampton and supported by Ángel Serrano-Aroca, Alberto Tuñón-Molina and Ángel Serrano-Aroca of the Spanish Catholic University – assessed the antiviral performance of AM materials that could offer the potential for preventative virus transmission and on-demand manufacturing.

“Virus transmission can be direct (human-to-humans) or indirect (airborne and/or contaminated surfaces) including respiratory droplets and therefore face masks have been reintroduced and again have become mandatory in many community settings,” stated Dr Arjunan.

“As airborne droplets below five microns can contain infectious SARS-CoV-2 and can remain suspended in the air for three hours masks do offer some protection from the transmission,” he continued. “However, surfaces on the other hand can sustain infectious viruses from a few hours to nine days depending on the surface material and morphology. For example, stainless steel that is widely found in hospitals and medical settings can sustain SARS-CoV-2 survival for seven days. Therefore, with the emergence of potential vaccine evasive variants antiviral materials that inactivate the virus offer much potential for transmission prevention.”

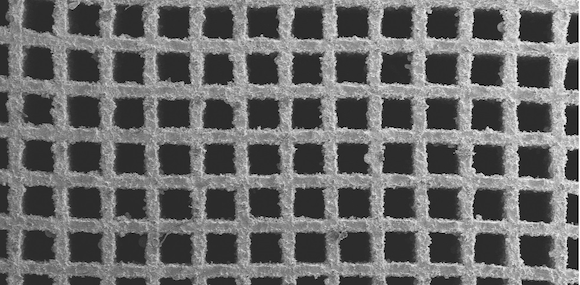

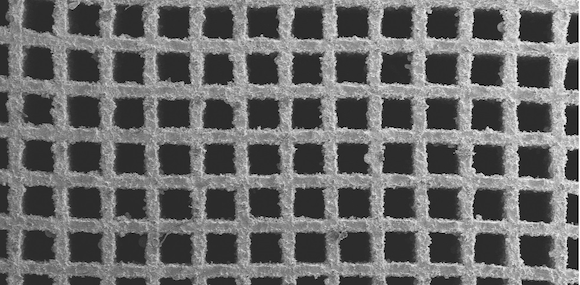

The interdisciplinary team used Laser Beam Powder Bed Fusion (PBF-LB) AM to manufacture a novel microporous architecture and assess the anti-viral performance of Cobalt-Chromium-Molybdenum (Co-Cr-Mo), already an alloy in common use in industrial AM settings for medical and aerospace applications.

Lead researcher John Robinson stated, “The Co-Cr-Mo material was shown to have potent antiviral activity displaying a significant improvement on copper and silver alloys which are well known for their antimicrobial properties. To our knowledge, we are the first to assess the anti-SARS-CoV-2 efficacy of Co-Cr-Mo which displayed 100% viral inactivation in thirty minutes. Therefore, our latest publication proves [PBF-LB] and Co-Cr-Mo could be adopted for antiviral mask filters and heating, ventilation, and air conditioning filtration systems for healthcare and general community settings. Additionally, Co-Cr-Mo could be used for door handles or other touchpoints where high potential for virus transmission could be reduced or eliminated.”

The peer-reviewed paper is available in full here.