Research yields positive results for Electron Beam AM of molybdenum

April 14, 2021

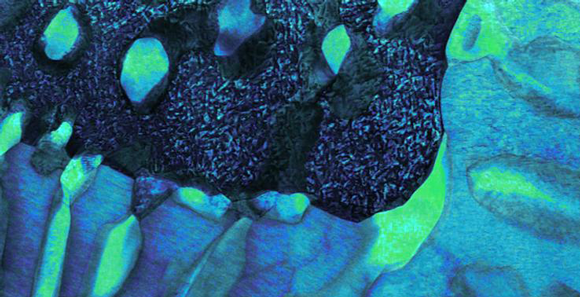

Researchers at Oak Ridge National Laboratory (ORNL), Oak Ridge, Tennessee, USA, recently used Electron Beam Powder Bed Fusion (PBF-EB) to produce parts from molybdenum titanium carbide, a refractory metal alloy, and found that the material could be both crack free and dense when produced by PBF-EB. These findings indicate the material’s viability for Additive Manufacturing.

Molybdenum (Mo) and its associated alloys are difficult to process through traditional manufacturing because of their high melting temperatures, reactivity with oxygen and brittleness. To address these shortcomings, the team formed a Mo metal matrix composite by mixing molybdenum and titanium carbide powders. At Oak Ridge National Laboratory, an electron beam was used to melt the mixture, offering the ability to control the cooling rate, thereby optimising performance.

“Our results showed that fabrication from a mechanically alloyed metal matrix composite powder is feasible,” stated ORNL researcher Mike Kirka. “The structures formed by the fused powders can withstand high temperatures, indicating that molybdenum and its alloys can be used for aerospace and energy conversion applications.”