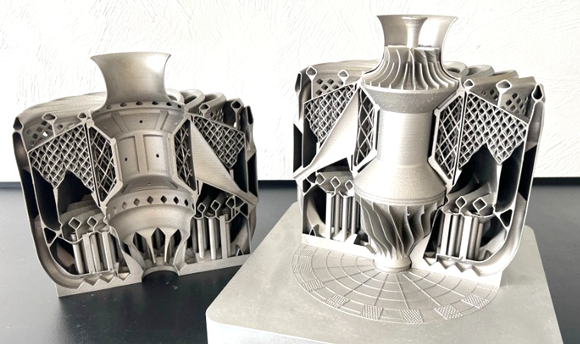

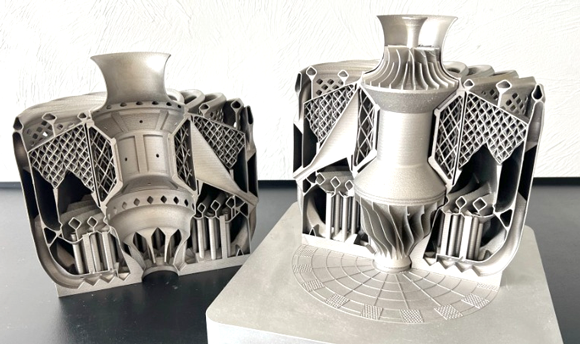

PTC showcases fully additively manufactured jet engine at LiveWorx 2023

May 24, 2023

PTC, Boston, Massachusetts, USA, showcased a fully additively manufactured jet engine at the recent LiveWorx 2023, event in Boston, USA. PTC’s micro turbojet engine, weighing approximately 3.6 kg and additively manufactured from Inconel, is a single, complete assembly, including all rotating and stationary components, and was designed in PTC’s Creo CAD software.

The jet engine project was conceived by Dr Ronen Ben Horin, VP of Technology at PTC and Senior Research Fellow at Technion – Israel Institute of Technology, and Beni Cukurel, an Associate Professor of Aerospace at Technion. Designing and additively manufacturing a fully self-supported micro turbojet engine, including the 50,000 RPM turbine, that requires no assembly, is said to represent a significant breakthrough in designing for Additive Manufacturing (DfAM).

Many of the Creo advanced design capabilities were used for the jet engine assembly. The software is said to enable sophisticated lattice modeling and generative design for material and weight reduction while maintaining the same strength and performance of designs with more material and heavier weight. Beam-based lattices in Creo automatically optimise designs for AM and the software also supports self-supported formula-driven lattices that can be paired with build checks and modifiers to adjust the design for AM efficiency.

Creo is compatible with most AM equipment for build and post-processing. PTC explained that the 3D component design in Creo is critical for performing traditional machining for precise assembly. Creo also provides a variety of formats, including 3MF, for sending 3D models to the market’s various printer technologies, while also allowing users to easily create associative models for machining operations.

Download Metal AM magazine