Protolabs launches manufacturability analysis platform

February 10, 2023

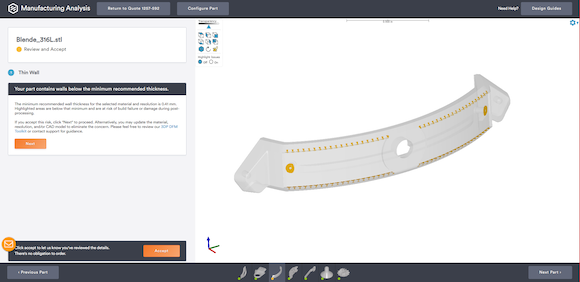

Protolabs, with global headquarters in Maple Plain, Minnesota, USA, and manufacturing facilities and offices in Europe, USA and Japan, has launched its Design for Manufacturability analysis aimed at customers across Europe. The platform will allow users to test the suitability of additively manufactured parts, before committing to production, in seconds.

“Additive Manufacturing is a brilliant technology, allowing engineers to produce complex parts that were previously too difficult to achieve,” stated Andrea Landoni, Protolabs EMEA’s 3D Printing Product Manager. “Whilst the technology offers great flexibility, there are a few limitations that engineers must be aware of and the Design for Manufacturability (DFM) analysis provides that guidance in seconds. The system will instantly highlight all the issues to the user, whether they are critical, such as parts that are too large to be produced, or non-critical, like dimensions that are close to certain thresholds like wall thickness and may not form completely.”

“We understand the importance of speed, but ensuring that parts are correct, high quality, and delivered rapidly is critical,” Landoni added. “Instant analysis means you can have all the advantages of Additive Manufacturing with even more certainty without sacrificing speed.”

Design for Manufacturability processes are intended to eliminate lost-time incidents for most common issues, preventing engineers from proceeding with their order only to discover later that there were issues. The platform will be supported by advice from Protolabs’ Application Engineers where needed.

“The Design for Manufacturability analysis supports our Application Engineers by reducing the number of projects they need to get involved in, allowing them to interact with more customers who require their support even faster,” Landoni concluded.

Download Metal AM magazine