Prima Additive to showcase its latest AM machines at Formnext 2021

September 27, 2021

Prima Additive, the Additive Manufacturing division of Prima Industrie Group, headquartered in Turin, Italy, will showcase its latest AM machines and technology at this year’s Formnext, taking place in Frankfurt, Germany, on November 16–19, 2021.

On show will be the Print Genius 150 Double Wavelength, a new addition to Prima Additive’s 150 series of Laser-Beam Powder Bed Fusion (PBF-LB) AM machines. Reported to make this machine unique is the innovative configuration of the laser sources: a 300 W infrared laser and a 200 W green laser, which can work alternately on the same work area. In this way it is possible to select the best wavelength for optimising the material absorption of the laser radiation. For instance, you can choose IR radiation for steel alloys, titanium, nickel, chromium-cobalt, or green radiation for pure copper, aluminium or other highly reflective materials. The Print Genius 150 Double Wavelength features a build volume with a diameter of 150 mm and a height of 160 mm.

Also on display will be the company’s Print Genius 250, targeted at high productivity metal AM applications. The Print Genius 250 is able to reduce production times thanks to its 500 W single-mode dual laser, combined with an intelligent software for a quick orientation of the pieces and for the definition of the machine parameters. The build volume of 258 x 258 x 350 mm makes the machine suitable for the production of medium sized components.

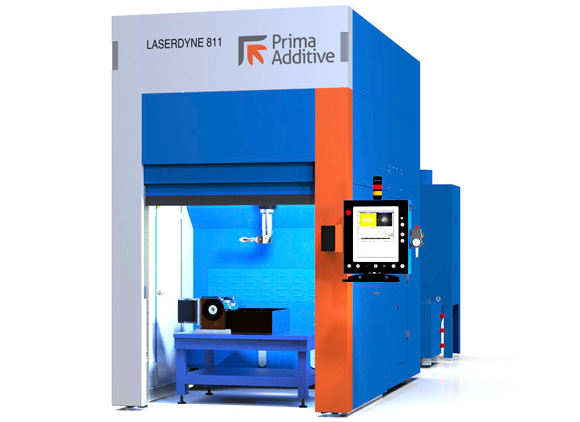

The latest development from Prima Additive for Direct Energy Deposition (DED) AM will also be on show. The Laserdyne 811 DED is said to be an extremely flexible solution, supporting additive, welding, drilling and cutting 3D and 2D components on a single machine. With a working volume of 1100 x 800 x 600 mm, the machine can be equipped with the company’s REAL_DED (REal-time Adaptive Laser beam for Direct Energy Deposition) laser deposition head. Developed and patented by Prima Additive, this allows increased the performance and the efficiency of the deposition process, and allows the end-user to adapt the laser beam spot dimensions in real-time during the build process.

Prima Additive plans to deliver live demonstrations of the exhibited machines, with experts from the company on hand to discuss the complete range of services it offers.