PostProcess partners with Materialise on CO-AM platform and depowdering technology

November 16, 2022

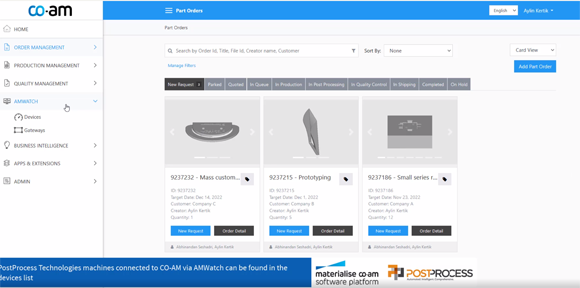

PostProcess Technologies has partnered with Materialise to integrate its CONNECT3D software with Materialise’s CO-AM open software platform. Users can now manage, organise and coordinate all PostProcess solutions from a unified system to fulfil project requirements. This is intended to ultimately help reduce production errors, minimise downtime and improve efficiency with end-to-end visibility and control over the production process.

In addition to this software integration milestone, Materialise recently chose PostProcess’ patent-pending Variable Acoustic Displacement (VAD) technology for automated powder removal. VAD leverages software intelligence to optimise mechanical energy and closed-loop thermal and displacement techniques for unmatched bulk de-powdering results. The powder removal and recovery achieved with VAD enables full process chain automation, providing customers like Materialise with enhanced sustainability & employee safety, repeatability & productivity, and lower overall operating costs.

Materialise selected the comprehensive VAD solution to automate the gross de-powdering of its additively manufactured production parts. VAD is expected to enable a scalable and more sustainable manufacturing workflow, connecting the AM digital thread by making use of the CONNECT3D platform and providing seamless integration with the Materialise production environment.

“We are excited to partner with Materialise to provide AM users everywhere with the automation they have been seeking for a long time,” stated Jeff Mize, CEO at PostProcess. “Materialise shares our vision for a more connected and sustainable Additive Manufacturing future, which is further evidenced by our collaboration on CO-AM and our VAD technology.”

Bart van der Schueren, CTO and EVP, Materialise, added, “At Materialise, we value meaningful innovation, and we remain steadfast in our mission to innovate product development and manufacturing in ways that result in a better, safer and healthier world. Our collaborations with PostProcess to integrate our platforms and achieve an automated, sustainable post-processing solution in VAD directly support this mission.”