Pandemic reinforces focus on Additive Manufacturing at DMG Mori

August 25, 2020

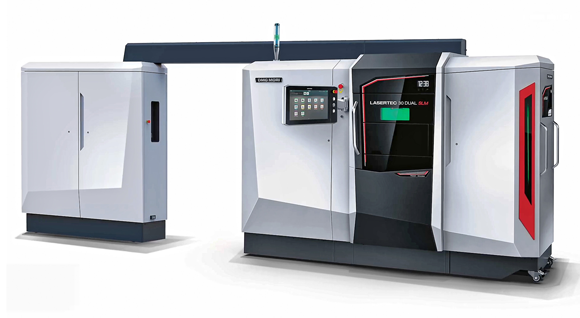

DMG Mori’s Lasertec 30 Dual SLM machine, a Laser Powder Bed Fusion (PBF-LB) machine (Courtesy DMG Mori)

DMG Mori, headquartered in Bielefeld, Germany, has reported its financial results for the first half of 2020. The group is one of the largest producers of cutting machine tools globally, as well as a developer of Directed Energy Deposition (DED), Laser Beam Powder Bed Fusion (PBF-LB) and hybrid metal Additive Manufacturing technologies.

Like most companies, DMG Mori stated that it had felt the effects of the coronavirus (COVID-19) pandemic, and a corresponding decline in the global demand for machine tools. Order intake, sales revenues and earnings for the first half of 2020 were significantly below the high figures of 2019.

The company reported order intake of €784 million for the first half of the year, down from €1,412.3 million in 2019. Sales revenues were €838 million (2019: €1,276.4 million), with an EBIT figure of €33.2 million (2019: €103.4 million) and an EBIT margin of 4% (2019: 8.1%).

Responding to the results, Christian Thönes, Chairman of the Executive Board, stated that the coronavirus had accelerated many of the company’s customers’ transitions to the digital factory model, reinforcing the group’s focus on its advanced and digital technology offerings.

“This strengthens our intention to further expand our future fields of automation, digitisation and Additive Manufacturing,” he commented. “Investing in innovations, and especially in digitisation, is the only way out of the crisis. The economic situation is and remains challenging. But we are well-positioned and will continue to have positive results.”

Recognising the importance of digital manufacturing solutions, including Additive Manufacturing, to aid in the manufacturing industry’s recovery, the group noted that in the financial year 2020 it will present thirty-five new innovations, including three automation solutions, twenty “digital innovations” and two new DMG Mori components.

Looking ahead to the second half of 2020, the company reflected that the global market for machine tools will decline sharply. In their April forecasts, the German Association of Machine Tool Builders (VDW) and the British economic research institute, Oxford Economics, forecast growth in global consumption to fall significantly by 28.3% to €52.3 billion.

Due to the complete change in the global economic conditions, DMG Mori stated that it expects a sharp decline in order intake, sales revenues, earnings and free cash flow over the full financial year 2020.

Despite these challenging conditions, the company believes that its cost reduction and flexibilisation measures, initiated early in all areas, will support its performance and profitability. These measures, in addition to the further expansion of its Additive Manufacturing, automation, and digitisation efforts, are expected to grant DMG Mori resilience against the ongoing situation.