ORNL researchers use neutrons to discover strengthening behaviour in additively manufactured alloys

January 25, 2023

Researchers at Oak Ridge National Laboratory (ORNL), Tennessee, USA, are reported to have identified a mechanism in an additively manufactured alloy, termed load shuffling, that could enable the design of higher-performing, lightweight materials.

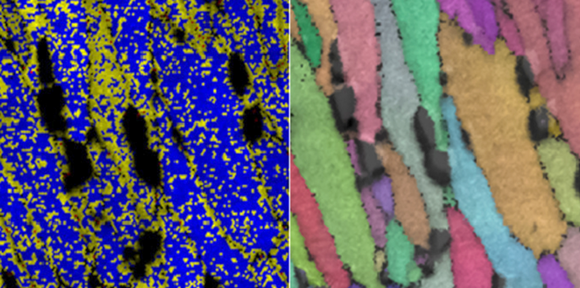

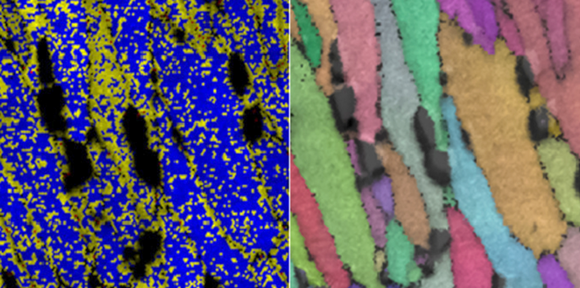

The team monitored high-temperature deformation behaviour of an additively manufactured Al-Cu-Mn-Zr alloy in the as-fabricated and heat-treated states, using traditional ex-situ and in-situ neutron diffraction creep experiments performed at 300°C.

Using neutron diffraction enabled researchers to study the material’s atomic structure. They observed that the overall stress was absorbed by one part of the alloy but transferred to another part during deformation. This back-and-forth shuffling is said to prevent strengthening in some areas.

“Neutrons offer opportunities to study metallurgical phenomena in multiphase structural materials,” stated ORNL’s Amit Shyam, who co-authored the paper “Load shuffling during creep deformation of an additively manufactured AlCuMnZr alloy” published in Acta Materialia, volume 244. “We’ve gained unprecedented insight into elevated-temperature material behaviour that will allow us to design improved aluminium alloys for extreme conditions.”

The team see opportunities for improving energy efficiency in vehicles through the use of lighter, aluminium-based materials.