Optomec showcases hybrid atmosphere controlled system for metal Additive Manufacturing at AMUG 2018

April 9, 2018

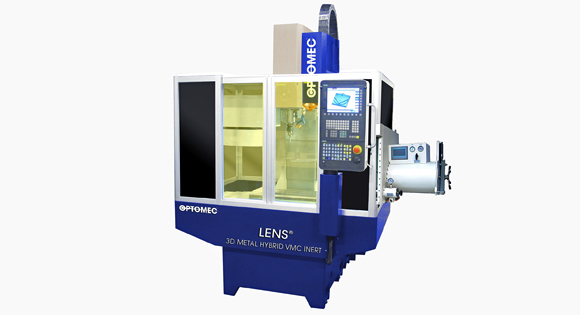

Optomec’s LENS 3D metal hybrid atmosphere controlled system (Courtesy Optomec)

Optomec, Albuquerque, New Mexico, USA, showcased its LENS systems for metal Additive Manufacturing at AMUG 2018 in St Louis, Missouri, USA, this week. In the exhibit hall, the company offered live demonstrations of Optomec LENS technology and video presentations of its atmosphere controlled LENS Hybrid System for the additive and subtractive processing of metals, including titanium and aluminium.

Optomec also gave several presentations as part of AMUG’s conference programme. Members of Optomec’s team discussed the latest breakthroughs in metal AM and printed electronics in a trio of talks:

- “The Quiet Transition to Additive Manufacturing in Series Production”, Ken Vartanian, Optomec VP of Marketing. Vartanian discussed a variety of less well known AM applications currently used in production for repair/manufacturing, consumer electronics and structural health monitoring.

- “Powder Bed Fusion vs Directed Energy Deposition: A Case Study in Speed”, Lucas Brewer, Optomec LENS Applications Manager. In his presentation, Brewer compared the capabilities of Powder Bed Fusion (PBF) and LENS Directed Energy Deposition (DED) Additive Manufacturing, where each is best applied, and the results from an independent benchmark study comparing performance and cost.

- “Functionalizing Structures via Aerosol Jet 3D Printed Electronics”, Bryan Germann, Optomec Aerosol Jet Product Manager. Germann discussed how Aerosol Jet technology is used in high-volume consumer electronics applications, structural health monitoring and 3D semiconductor packaging.

Optomec’s LENS 3D hybrid technology combines a CNC automation platform with LENS technology, which it says helps lower the acquisition cost for companies to adopt metal Additive Manufacturing. This product line includes four models, each designed to reduce manufacturing process times and costs while enabling improved end product performance. The additive only, open atmosphere model has a build envelope of 500 x 300 x 500 mm has an entry price of around $300,000.

Optomec has sold over three hundred systems to more than two hundred marquee customers around the world, targeting production applications in the electronics, energy, life sciences and aerospace industries.