Open Mind Technologies releases latest hyperMILL software update

January 20, 2021

Open Mind Technologies AG, headquartered in Wessling, Germany, a developer of CAD/CAM software solutions, has released latest hyperMILL® 2021.1 CAD/CAM software suite which offers users new and enhanced features for efficient 3D, five-axis and mill/turn machining.

Key features include a new Interactive Edit Toolpath capability which enables toolpath editing after initial generation. This is said to be especially productive for optimising tool and mould making, as the editing feature is marked for its ease of use and offers programmers the flexibility to adapt toolpaths by trimming and removing sequences accordingly for component conditions.

The company explains that to streamline access to Product Manufacturing Information (PMI) and metadata, hyperMILL 2021.1 offers a new import function that retrieves face quality information and metadata when importing CAD data from neutral or native formats and attaches data to the imported faces in hyperCAD®-S, making the information available to hyperMILL and its machining processes.

“We are dedicated to maximising and simplifying the user experience with hyperMILL by adding innovative and enhanced features and strategies,” stated Alan Levine, Managing Director of Open Mind Technologies USA, Inc. “Keeping pace with evolving CAD/CAM programming requirements and laying the foundation for future needs are both vital. In one example, the new PMI and Metadata Import feature in hyperMILL 2021.1 supports future-oriented data formats that will eventually eliminate the need for blueprints.”

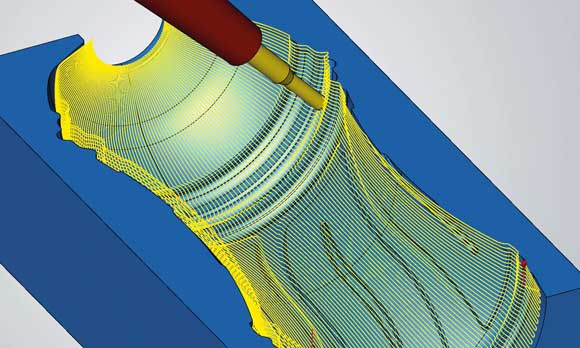

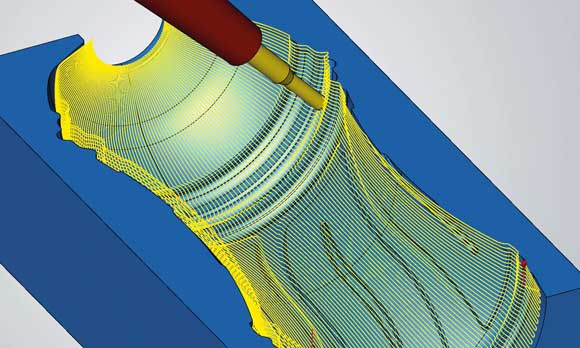

A new five-axis Radial Machining strategy allows bottle shapes and similar cavities to be easily and efficiently programmed in hyperMILL, resulting in high-quality surface finishes. Using a new radial projection method, toolpaths are calculated quickly so that the most productive machining strategies can be applied. For optimal high precision machining, hyperMILL High Precision Surface Mode and Smooth Overlap strategies can also be applied when using five-axis Radial Machining, ensuring the best surface quality and clean transitions.

Open Mind states that the HyperMILL 2021.1 provides a new, powerful SIMULATION Center for generic NC data in turning and milling operations. Modelled after the hyperMILL VIRTUAL Machining Center, the new, modern SIMULATION Center is integrated into hyperMILL and offers an intuitive operating environment for faster simulation, independent collision checking and extensive analysis functions.

Additional new features in hyperMILL 2021.1 include a new, easy-to-use XY Optimization command for optimal 3D profile finishing. In the hyperMILL Mill-Turn Module, the high-performance mode has been integrated into a three-axis simultaneous roughing strategy, combining the advantages of HPC and simultaneous turning. For the simplified alignment of components, hyperCAD-S has a new Align Best Fit machining command that allows like-geometry components to be aligned with one another using defined pairs of points.