Open Additive and Addiguru announce updated AMSENSE Chimera with Recoat+ for EOS machines

March 23, 2023

Open Additive, LLC, Beavercreek, Ohio, USA, and Addiguru, LLC, Metairie, Louisiana, have announced the newest edition of the AMSENSE Chimera with Recoat+, a third-party solution for identifying and gathering data suitable for process analysis and assessing build failures in the Additive Manufacturing process.

The new offering is specially designed and tuned to identify recoat process issues common on EOS M400 and M290 machines, providing a sensing platform which is intended to increase throughput and decrease build failures on critical the Laser Beam Powder Bed Fusion (PBF-LB) machines used in the aerospace market.

The EOS M400 and M290 machines themselves don’t analyse the quality of the recoating process, meaning operators and engineers are not able to receive timely feedback during the build process. Consequently, parts may fail and only the symptoms – such as a recoater crash – are recorded when the underlying problem may be unoptimised parameters, poor support structure design, or a rash of other issues. Oftentimes the issue that eventually leads to scrappage of the part is not detected for weeks or months later. This drives significant cost into a part. Timely actionable information on the health of the process facilitates quick root-cause analysis and correction.

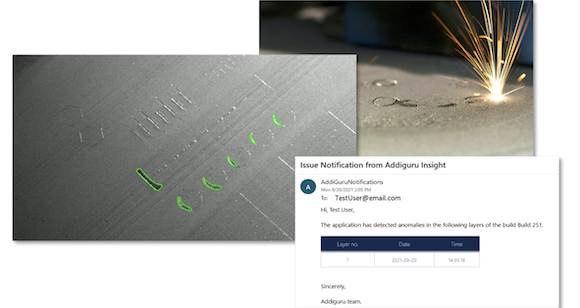

Open Additive partnered with Addiguru to leverage their machine learning based recoat analytic and notification schema. Near real-time recoat process anomaly detection on an M290 or M400 is built on the state-of-the-art sensing and analytics platform from Open Additive, AMSENSE, with a non-invasive installation and completely reversable package. Detectable issues include shortfeeds, part peel up, recoater hopping, recoater streaking, and other issues that result in recoater crashes or part non-conformance. The AMSENSE Chimera with Recoat+ solution is intended to provide operators with both visual and emailed notifications for when issues are identified, allowing timely action to be taken to salvage the parts, or restart the process. The solution also provides build health reports, generated at the end, to summarise potential issues, which can be used in downstream NDE and part acceptance processes.

“Years ago, I saw the adoption of additive unnecessarily slowed by the lack of proper process control mechanisms and the enormous costs borne by early adopters because of this dearth.,” stated John Middendorf, Director of Engineering. “With EOS being such a large presence in aerospace and medical manufacturing, we set out to marry early detection of the underlying causes of common problems encountered by many customers that result in build non-conformance, with a non-invasive installation of sensors tailor made to identify them and provide timely alerts to our users.”

Those interested in adopting AMSENSE Chimera with Recoat+ on EOS machines can contact Open Additivei, which will provide and installation and a support engineer.

Download Metal AM magazine