Norsk Titanium to build world’s first industrial-scale aerospace Additive Manufacturing plant in New York

July 11, 2016

Norsk Titanium AS has announced that the State of New York, USA, in partnership with the State University of New York (SUNY) Polytechnic Institute, has placed an order for 20 of the company’s MERKE IV™ Rapid Plasma Deposition™ machines in a deal that will create what is claimed to be the world’s first industrial-scale metal Additive Manufacturing plant.

The order is in accordance with an approved state budget allocation that will enable Norsk Titanium’s US subsidiary to build and operate the world’s first Rapid Plasma Deposition™ factory in Plattsburgh, New York, USA. The new facility is expected to be operational by the end of 2017

A $125 million New York investment in the Norsk Titanium US Plattsburgh factory was approved in the 2016-2017 State budget and first highlighted by Governor Cuomo on April 1, 2016. Under the terms of the deal, Norsk Titanium US will provide additional investment into the Plattsburgh operation that is anticipated to bring the total program commitment to the $1 billion dollar level over the initial 10-year period of operations.

“We are proud to be a part of the unwavering vision and leadership of Governor Cuomo and are moving forward in support of his efforts to revitalise upstate New York with jobs, technology and community pride,” stated Norsk Titanium Chairman of the Board John Andersen, Jr. “Our researchers have spent ten years pioneering the Rapid Plasma Deposition™ process that is now ready to cut millions of dollars in cost from the world’s premier commercial and military aircraft, and with the foresight displayed in other sectors, the State of New York is the ideal place to launch this manufacturing revolution.”

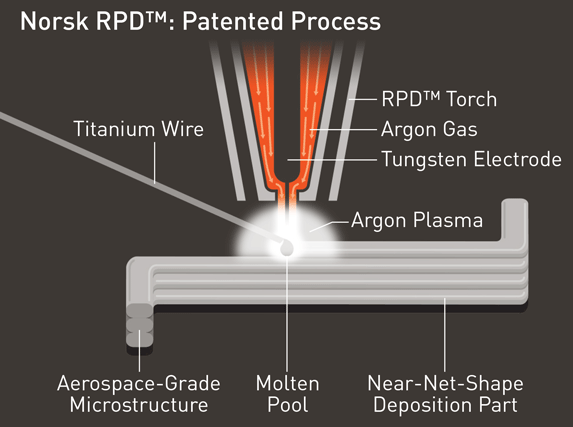

Norsk Titanium’s proprietary RPD™ process works by feeding titanium wire into a set of plasma torches protected by a cool argon environment that has made it possible to replace legacy forged parts, which take months and even years to develop and produce, with precision, additive manufactured components. Norsk Titanium RPD™ components have equivalent strength to forgings, but are delivered inexpensively and efficiently, with unprecedented part cost and design-to-market speeds.

“Today marks the beginning of a new era in the way aircraft, marine vessels, automobiles, spacecraft and many industrial products are designed and built,” added Norsk Titanium President & Chief Executive Officer Warren M. Boley, Jr. “Not only are we creating jobs, huge economic impact and great visibility for the wider Plattsburgh community, we are also making history by kicking off a new phase of on-demand, near-net-shape manufacturing that sets a new benchmark of efficiency and customer responsiveness.”

Norsk Titanium US is also partnering with the North County Chamber of Commerce in Plattsburgh to support and promote the successful launch and growth of Norsk’s industrial-scale factory including workforce training, economic development and STEM outreach including specific educational programs for SUNY Plattsburgh, local community colleges and other schools in the region.

“This unparalleled investment by Governor Andrew Cuomo in the North Country’s aerospace sector brings together a leading-edge global company in Norsk Titanium with an established high-tech aviation ecosystem in the region and the state, a perfect match that will create good paying advanced manufacturing jobs in Plattsburgh while advancing New York’s leadership in this dynamic and growing industry,” stated SUNY Polytechnic Institute Vice President Christopher Walsh. “SUNY Poly is proud to partner with Norsk Titanium to bring this revolutionary technology to market and to continue to drive cutting edge research in all of the state’s nanotechnology-enabled industries.”