Nikon acquires Avonix Imaging to strengthen X-Ray digital inspection solutions

July 20, 2023

Nikon Americas Inc, the US subsidiary of Nikon Corporation headquartered in Melville, New York, has purchased the US company Avonix Imaging LLC, Maple Grove, Minnesota, USA. Avonix has been a strategic X-ray CT equipment manufacturing partner to Nikon Industrial Metrology Business Unity (IMBU) since 2015.

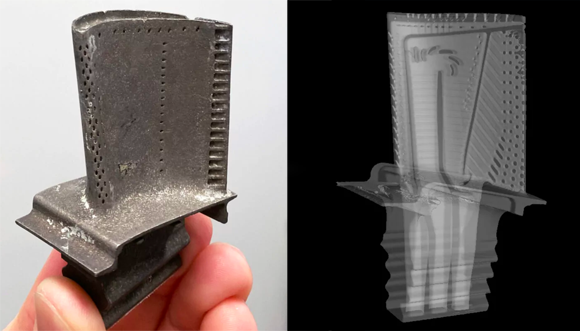

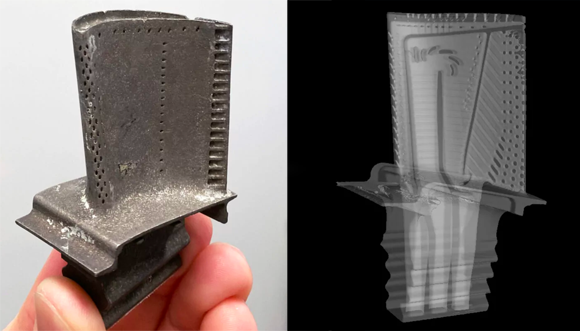

As a long-established imaging inspection services provider, Avonix uses systems from Nikon for both X-ray/CT 3D and 2D inspection, using its expertise to investigate the interior and exterior of industrial components.

Tadashi Nakayama, Corporate Vice President, General Manager of the IMBU stated, “Merging the respective strengths of our companies will reinforce our position as market leader in 3D and 2D X-ray inspection and measurement. It will massively enhance our ability to deliver best-in-class, next-generation solutions to the manufacturing industry.”

“In the run-up to making Avonix a wholly-owned subsidiary, we worked intensively with them to develop and build new X-ray CT systems with medium to large inspection envelopes. We recently launched a new model that realises the largest imaging area for a single-piece cabinet in the industry. Work on expanding this revolutionary machine series and other new products is continuing apace,” continued Nakayama.

Referring to the partnership, Brian Ruether, Co-Founder and Co-Managing Director of Avonix contributed, “Nikon’s proprietary rotating target X-ray sources and proven software combined with our expertise in the design of configurable systems, controls, and product handling create a customised experience for our clients, which can contribute to their efficiency and profitability.”

Jeff Diehm, Co-Founder and Co-Managing Director of Avonix added, “The historical collaboration between Nikon and Avonix has been rooted in the goal of mutual success for all involved, including partners, vendors and, of course, our customers. It is no coincidence that the goal of mutual success is at the heart of Avonix’s ACE Core Values (Authenticity, Competency and Empathy). The merger will result in enhanced value through the release of new and innovative products. We are excited to take our long-standing strategic relationship to the next level.”

Nikon and Avonix have been working together for the past eight years to jointly develop, build, sell and provide services relating to CT systems for large-scale inspection. Together, the two companies reportedly aim to further advance the development of new products going forward, while enhancing the business by leveraging the customer experience, especially in the automotive and aerospace industries. It is notable that, in its medium-term management plan from SY2022 to FY2025, Nikon has positioned digital manufacturing as its key strategic business.

Download Metal AM magazine