New system allows X-ray imaging of Electron Beam Powder Bed Fusion in real time

April 13, 2022

A team of mechanical engineers from the University of Wisconsin-Madison, USA, has developed what is reputedly the first system for concurrently using synchrotron X-ray imaging and diffraction, with complementary thermal and visible light imaging, to fully study the Electron Beam Powder Bed Fusion (PBF-EB) Additive Manufacturing process in real time.

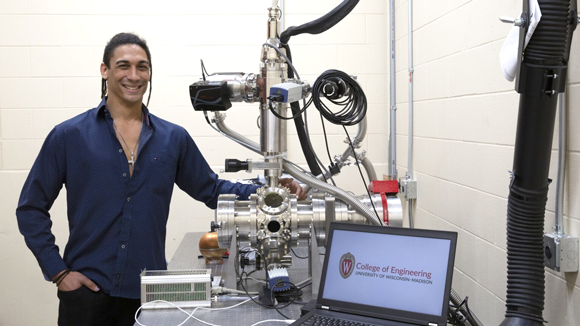

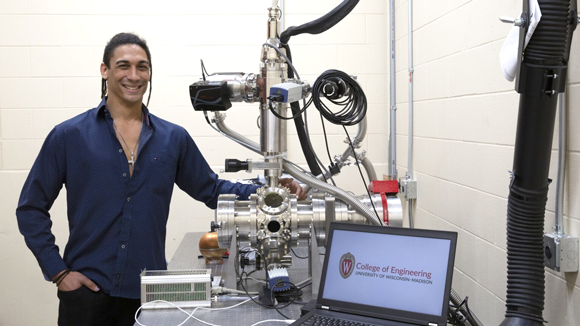

Led by Mechanical Engineering Assistant Professor Lianyi Chen, the team from the University of Wisconsin-Madison created an integrated system which is seen as a major step forward in the understanding of the fundamental mechanisms underlying PBF-EB Additive Manufacturing, which has previously been limited to what is visible on the surface.

“For Electron Beam Powder Bed Fusion, right now, there’s pretty fast growth,” stated Chen. “It’s an important technology to make parts for aerospace – for example, for jet engines, with titanium aluminide. We can’t make these with any other 3D printing technology.”

The team completed its system in early January 2022 and is said to have already tested it successfully on the Advanced Photon Source, an ultra-bright, high-energy synchrotron X-ray user facility at Argonne National Laboratory, Lemont, Illinois.

“It is the first time we have the ability to see what happens beneath the surface – what are the defect formation mechanisms,” Chen added. “With a deeper understanding of the process, we can design better technology to move the process to a much higher level.”

Like an X-ray of the human body, the high-energy synchrotron X-ray enables the researchers to see how the material is behaving within the entire part as it’s being additively manufactured. A thermal camera on the researchers’ system allows them to study how the temperature evolves during the process, while a visible light camera enables them to study the part’s evolving surface morphology.

“It is quite fascinating,” stated Luis Izet Escano, the mechanical engineering PhD student in Chen’s group who led the development of the system. “With only one run on our machine, we are able to see several aspects of the printing process simultaneously.”

While the Electron Beam Powder Bed Fusion process seems straightforward, there are lots of physical phenomena at play. Today’s commercial Additive Manufacturing machines aren’t built for gathering such data from the synchrotron facility, meaning Escano and his colleagues had to design and fabricate their system from scratch.

For its design, the group drew on its experience building tools that allow them to use a synchrotron to study and improve Laser Beam Powder Bed Fusion (PBF-LB). The team also overcame several technical challenges associated with studying the Electron Beam Powder Bed Fusion process, including maintaining the high vacuum needed for the process, mitigating vibrations from the vacuum pump in their measurements, and manufacturing special viewports so that the synchrotron’s X-rays could pass through them effectively.

“Development and integration of the system has been a great challenge, as it requires expertise in multiple engineering areas,” continued Escano. “Now, the flexibility of our machine allows us to run experiments and collect data quite fast – and this will accelerate our research toward the fundamental understanding and perfection of this printing technology.”

More on this research is available here.