New DryLyte technology enables electropolishing of metal parts without liquids

July 26, 2018

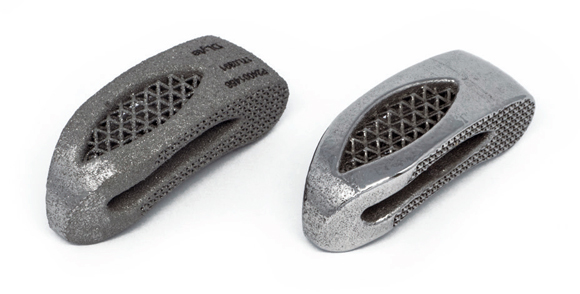

A titanium spinal implant with a smooth surface finish (right) achieved using DryLyte Technology (Courtesy DLyte)

DLyte, based in Barcelona, Spain, has developed a new patented technology for the automatic grinding and polishing of high-precision metal components. The company’s DryLyte® process is said to be the first dry electropolishing system, which uses no liquid as the electrolyte, and is suitable for for steel, stainless steel, aluminium and titanium components.

Grinding and polishing of metal parts is an important process step for removing the asperities and defects inherent in components following the initial build process. The removal of peaks, roughness, burs and micro-defects can dramatically improve the corrosion/oxidation resistance, lifespan and friction of a part. This is especially important for high-precision engineering applications such as those within the medical, automotive and aeronautics industries, where surface quality can be critical.

According to DLyte, DryLite was developed in response to problems the company identified in current grinding and polishing solutions, which it states can be highly time-consuming, extremely cost-intensive, and may render sub-optimal results failing to meet functional requirements.

DLyte states that its system does not leave micro-scratches on the surface of the workpiece and can achieve small corners –where abrasive polishing, for example, is not able to create enough movement and pressure to polish homogeneously. It is said to offer superior surface results, with Ra under 0.1 µm, without altering the geometry of the workpiece and while assuring excellent mechanical properties and highly-controlled composition.

It was stated that DryLite Technology is currently at a very early stage, but the company believes that it could “revolutionise the finishing industry,” given its wide range of applications. DLyte has established partnerships with a number of companies in the Additive Manufacturing industry, among them EOS, Renishaw, SLM Solutions and 3D Systems, as they look to offer a complete solution for customers and develop polishing solutions for the different materials and applications within the metal AM Industry.