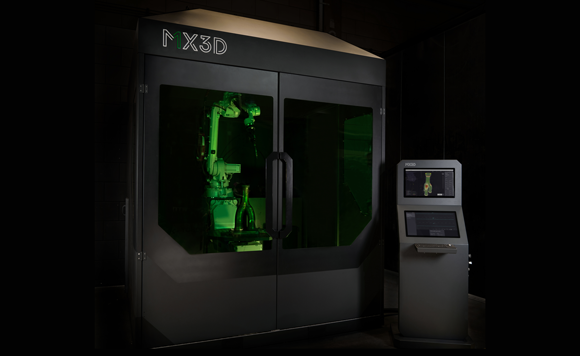

MX3D announces sale of M1 metal Additive Manufacturing machine to US Department of Defense

October 24, 2023

MX3D, Amsterdam, the Netherlands, has announced that the Engineer Research and Development Center (ERDC) of the US Department of Defense (DoD) in Vicksburg, Mississippi, USA, has purchased one of the company’s M1 metal Additive Manufacturing machines.

The new machine and is expected to be installed in Q1 of 2024 at the ERDC Geotechnical and Structures Laboratory (GSL), part of the US Army research centres.

“Serving the USA market and collaborating with the USA DoD is a significant achievement for MX3D. It reflects our dedication to grow our North-American presence. It also shows that our focus on high productivity, certification and automation is paying off,” stated Gijs van der Velden, CEO of MX3D.

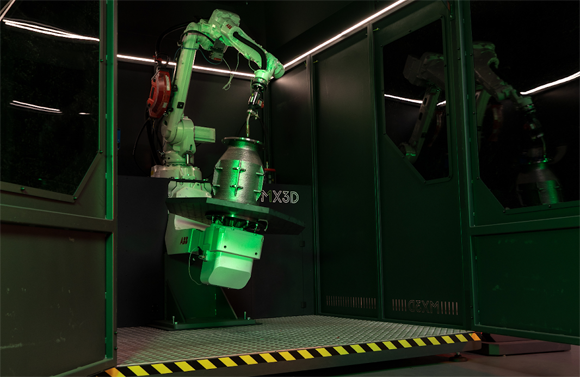

The M1 uses Wire Arc Additive Manufacturing (WAAM), a wire-based Directed Energy Deposition (DED) process and can manufacture components from a wide range of materials, including stainless steels (304/308/316/Duplex), steel (regular carbon, high strength, corten), aluminium (2000/5000/6000 series), and aluminium bronze.

“Many of these alloys are preprogrammed into the control system, enabling a quick start on parts made from new materials. This, combined with the CAM solely designed for WAAM, makes it an ideal machine for research institutes like the ERCR,” van der Velden told Metal AM magazine.

The M1 is capable of handling parts up to 750 kg with eight axes, and several tons with six axes. The build speed varies depending on the geometry, applicable standards, and alloy type but thin-walled parts typically have a deposition rate of 1-2 kg per hour, while thicker parts can be manufactured at a rate of 5-8 kg per hour.

Download Metal AM magazine