MPW and Solvus Global collaborate for Additive Manufacturing material development

November 6, 2023

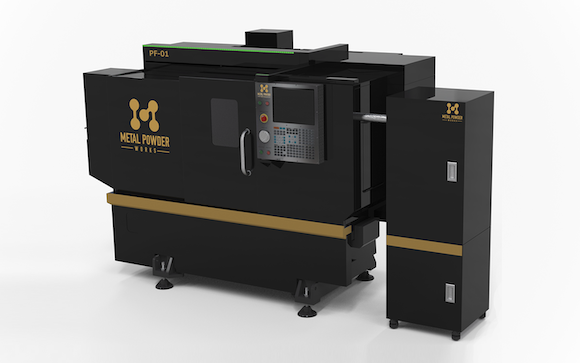

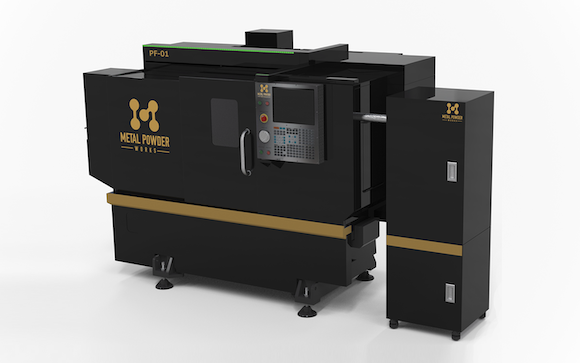

Metal Powder Works (MPW), based in Sewickley, Pennsylvania, USA, is partnering with Solvus Global, Leominster, Massachusetts, USA, to develop powders for use in the Additive Manufacturing industry. The partnership involves Solvus Global acquiring a DirectPowder™ machine from MPW, marking the first unit to be placed outside of MPW’s Pittsburgh production facility.

Under the terms of the alliance, Solvus Global and its business unit Powders on Demand, will be the first to join Metal Powder Works’ newly established Developer Network. This collaboration intends to allow startups to combine resources and expedite the production of existing alloys and challenging powders for the Additive Manufacturing sector.

The DirectPowder process converts metal bar stock into powder via a software-driven mechanical process at room temperature. The process is reported to result in powder with a PSD of about 30 µm, and every particle is identical, solving the issues of both consistency and size efficiency. Solvus Global, with the DirectPowder Unit at its disposal, is expected to have a competitive advantage in the clean production of existing materials that feed directly into its advanced powder production capabilities for Additive Manufacturing and coating systems.

Furthermore, as a key part of Metal Powder Works’ Developer Network, Solvus Global will gain unparalleled access to a broad range of materials not yet available as powder. This is anticipated to significantly decrease the time and cost to access vital resources for innovative projects.

“We’re excited to lead the way in economic production of powders starting at R&D all the way through commercial scale to enable our public and private sector customers to push the boundaries of AM and coatings,” stated Brad Richards, CEO, Powders on Demand .

Aaron Birt, Solvus Global co-founder & CEO, added, “There are only sixteen approved AMS [Aerospace Material] specifications for powder today while there are more than 2,000 approved AMS specifications for bar stock. AM needs more than sixteen alloys to be successful.”

John Barnes Metal Powder Works’ CEO and founder commented, “We’ve known the people at Solvus Global for a very long time, even before MPW existed. It is crucial for us to help the AM community by making more materials available in powder form, so every business case doesn’t automatically require a change in material. Solvus Global understands the requirements of the various processes for powder, so this is a natural partnership.”

Metal Powder Works is exhibiting at Formnext 2023 in Hall 12.1, F139.

Download Metal AM magazine