Morf3D expands metal Additive Manufacturing capacity to meet aerospace orders

March 8, 2018

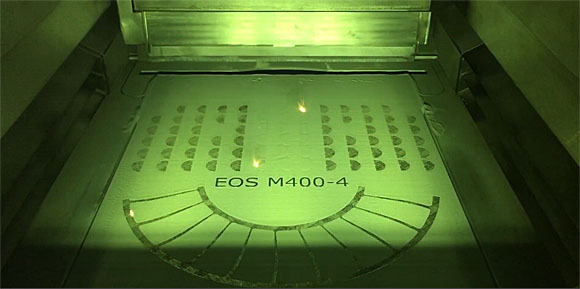

Morf3D states that it plans to acquire a total of ten EOS 400-4 metal AM systems in the coming months (Courtesy EOS)

Morf3D, an Additive Manufacturing design and production service bureau in El Segundo, California, USA, is reported to be purchasing ten of EOS’s flagship M 400-4 metal Additive Manufacturing systems. EOS confirmed that two systems have now been sold, with the remainder of the order to be finalised in the coming months.

The EOS M 400-4 machines are expected to be used, in part, to fulfil Morf3D’s recent engagement by Boeing and Honeywell to supply metal AM production flight hardware.

Ivan Madera, Morf3D’s CEO, stated, “The AM market is maturing and with that comes increased production demands with very stringent requirements. Not all organisations are prepared. We are, and will continue to add systems and processes to leverage the most reliable Direct Metal Laser Sintering technology in the world.”

“Our strong customer relationships, coupled with our AM lifecycle strategy, have quickly evolved from material qualification to production at-scale,” he continued. “We have been working diligently to put in place a very robust supply-chain with industry partners to exponentially increase our metal AM capacity and services.”

“When this phase of the investment is complete, Morf3D will boast ten EOS M 400-4 machines, one EOS M 400 and three EOS M 290s,” added Glynn Fletcher, President of EOS North America. “That is no small commitment by any stretch of the imagination. But, Ivan’s team has long track record of success and a clear vision regarding the market demand for AM capacity.”

“They are pursuing their entrepreneurial dreams with extraordinary vigour. We’re really proud to support them and reinforce their belief that EOS powder bed 3D printing technology is the surest way to achieve their goals,” he concluded.