ModuleWorks extends MAL partnership with physics-based machining software

March 14, 2024

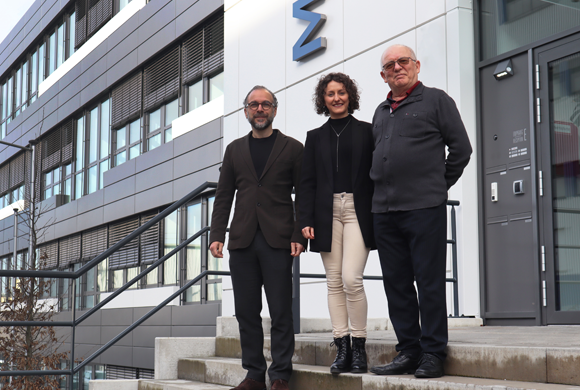

ModuleWorks GmbH, based in Aachen, Germany, has extended its partnership with MAL Inc, a developer specialising in physics-based virtual machining and optimisation solutions based in Vancouver, Canada.

The extended partnership makes ModuleWorks the exclusive reseller of MAL’s AppsPro software library as well as the NPro plug-in for SiemensNX and the DELPro plug-in for Dassault Systèmes DELMIA. In addition, ModuleWorks will sell the jointly developed Machining Wizard that integrates machining physics and toolpath technology to assist engineers in selecting optimal parameters for automated toolpath generation.

Professor Yusuf Altintas, founder of MAL, explained, “Even for seasoned CAM engineers, the task of selecting machining parameters to account for physical loads, vibrations and forces on the machine tool poses a challenge. The new Machining Wizard integrates our physics engine with the ModuleWorks toolpath kernel to bring CAM toolpaths closer to the real-world scenarios of actual machining and help engineers by automating and simplifying the selection process. We are excited by the reseller agreement which will bring this technology to a wider digital manufacturing audience.”

“Our technologies complement each other perfectly,” said Dr Yavuz Murtezaoglu, founder and Managing Director of ModuleWorks. “The industry needs integrated, highly automated solutions that simplify workflows and raise productivity across the manufacturing chain. Integrating machining physics with toolpath technology takes us closer to this goal.”

AppsPro and its plug-in derivatives NPro and DELPro are intended to optimise the feeds for a toolpath that has already been calculated. The Machining Wizard, on the other hand, simulates physical forces such as torque, bearing load and vibrations to give engineers the information they need for selecting parameters like cutting depths, widths, speeds and feeds. It then uses these parameters in combination with a geometrical analysis of the workpiece to automatically generate a toolpath with optimised cutting parameters for each region of the part.

“For the first time, machining physics, geometrical analysis and toolpath algorithms work hand-in-hand to enable even novice CAM engineers to expertly program parts,” said Julia Meyer Hendricks, Head of Business Development – Digital Manufacturing at ModuleWorks. “This exactly answers the skills-gap facing the industry.”

Download Metal AM magazine