ModuleWorks announces successful closure of Strategic Partner Program investment round

May 8, 2024

ModuleWorks GmbH, based in Aachen, Germany, has announced the successful closure of its Strategic Partner Program (SPP) investment round. This is said to mark a significant milestone in the company’s history, with industry leaders in the areas of CAD/CAM, CNC controls, machine tools and cutting tools joining the programme as minority shareholders in ModuleWorks. Investing partners include Autodesk Inc, DMG MORI AG, DN Solutions, Kennametal, Mitsubishi Electric Corporation and PTC Inc, among others.

“We embarked on this journey with a vision to accelerate digital transformation in manufacturing while maintaining our position of neutrality and independence,” shared Dr Yavuz Murtezaoglu, founder and Managing Director of ModuleWorks. “The successful closing of the SPP is a testament to our mission and the trust placed in us by our Strategic Partners: these are successful, billion-dollar organisations representing key links in the digital manufacturing chain. This achievement enables us to intensify our research and development, increasing our commitment to develop next generation software for manufacturing. In addition, it will enable us and our investors to develop a joint vision for the future of manufacturing.”

The Strategic Partnership Program was initiated with a clear focus on inviting key technology partners to invest in ModuleWorks and, by doing so, join forces in shaping the future of manufacturing. The range of investors represent the key stakeholders in digital manufacturing as well as multiple organisations from each area, emphasising ModuleWorks’ commitment to neutrality and independence.

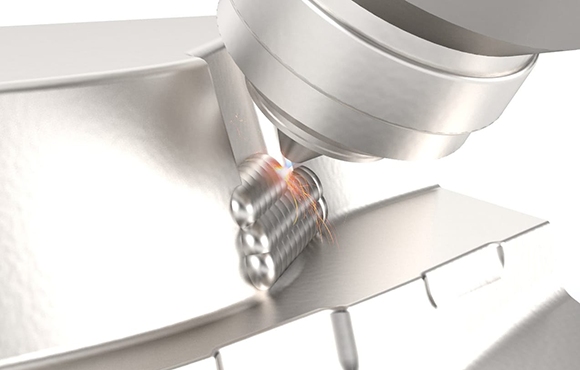

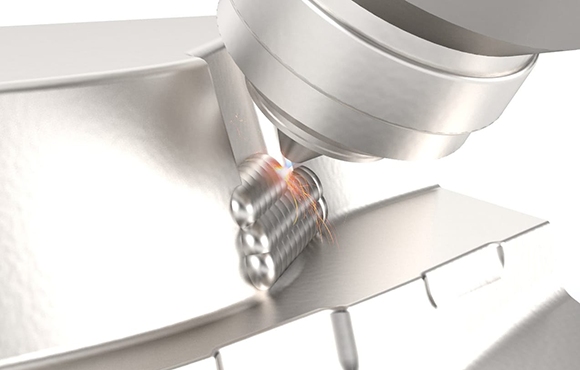

The investment will reportedly mainly be used to increase ModuleWorks’ Research & Development capacity with the objective of accelerating digital transformation in manufacturing by focusing on four key areas: CAM & CNC automation, advanced Additive Manufacturing, cloud computing, and robotics. Additionally, it is expected that some of the investment may be used for strategic acquisitions.

With the closure of this strategic investment round, ModuleWorks is said to be on target for an accelerated path of innovation in the area of toolpath and simulation components for digital manufacturing systems.

Download Metal AM magazine