MKS Instruments releases new Ophir BeamSquared M2 laser beam propagation analyser

February 7, 2024

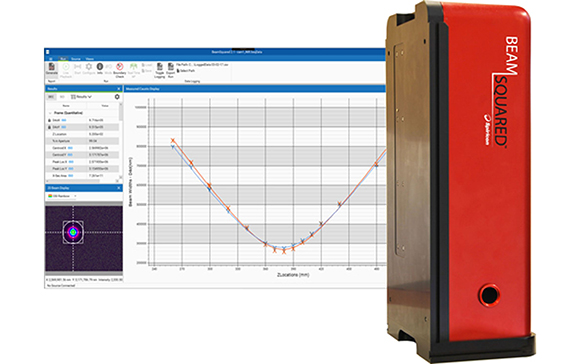

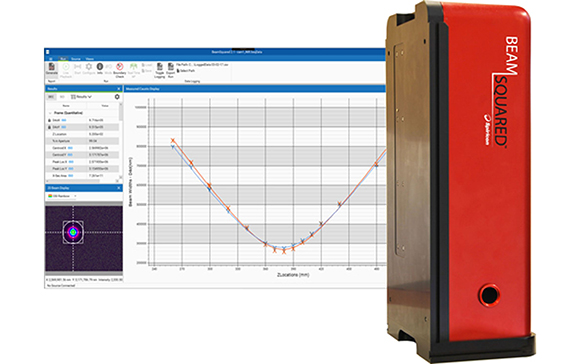

MKS Instruments, Inc., headquartered in Andover, Massachusetts, USA, has announced the release of the Ophir BeamSquared M2 beam propagation analyser. The BSQ SP204S M2 is a robust, portable device that helps users optimise laser performance automatically and accurately.

The system measures the propagation characteristics of CW and pulsed lasers with Rayleigh lengths up to 20 metres in less than one minute. The system uses CMOS camera technology and is reported to deliver higher spatial resolution, better sampling accuracy, and improved SNR (signal to noise ratio) than CCD-based cameras. Designed for continuous use applications, from scientific research to laser manufacturing to fabrication and machining, the BSQ SP204S M2 measures wavelengths from 266 nm to 10.6 µm, including CO2 and terahertz.

“Laser manufacturers and system integrators rely on fast and accurate caustic measurements in order to understand the laser beam’s quality, or focusability,” stated Reuven Silverman, General Manager, Ophir Photonics. “The use of CMOS technology in the BeamSquared SP204S beam propagation analyser brings a new level of performance across all levels of measurement. This includes increased sensitivity, reduced smearing effect, improved performance at all caustic parameters, and higher accuracy in NIR wavelengths. This means users can measure smaller beam sizes more accurately. The system is also ISO 11146 compliant, so users can trust the data.”

The BeamSquared SP204S M2 machine includes the BeamSquared software, an optical train, and a CMOS camera. The software is designed to measure beam propagation characteristics on both the X and Y axes, including waist diameters, full angle divergences, waist locations, Rayleigh lengths, M2 or K and BPP factors, astigmatism, and asymmetry. The system displays 2D or 3D beam profiles for visual verification of beam behaviour through focus. Functions include a 3D slice display and the ability to add 3D displays to reports.

Reports can also incorporate a beam caustic chart, in addition to setup information, laser measurements, and a variety of statistics. An automation interface via .Net components allows users to build custom applications that incorporate the laser beam analysis and processing power of the BeamSquared system.

All BeamSquared systems can be mounted horizontally or vertically to optimise bench space. Each is equipped with conventional focusing lenses of 400-600 mm. Specially calibrated 750 mm and 1000 mm lenses are optionally available for use with long Rayleigh range lasers (20 m) that involve both a long-waist location and small focal spot size.

Download Metal AM magazine