Mimete releases new iron-base powders F51 and F53 for demanding applications

November 10, 2020

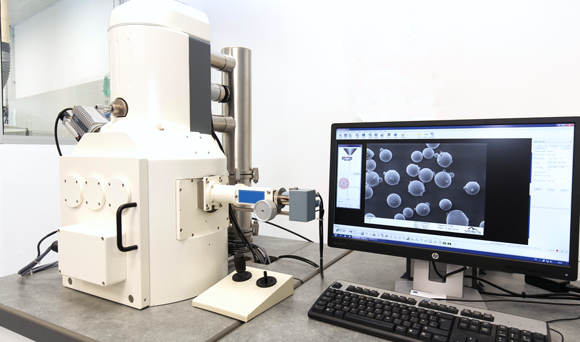

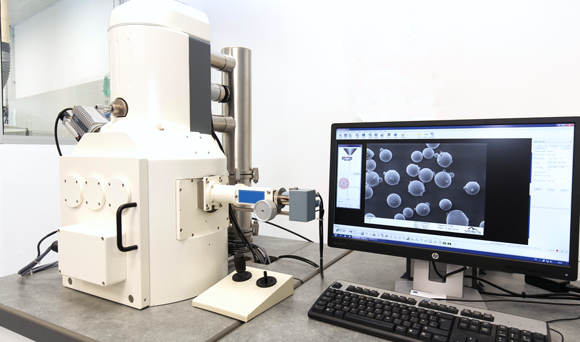

Mimete S.r.l., Osnago, Italy, has released two new iron-base powders, Duplex MARS F51 and Super-duplex F53. The company, a division of Italy’s Fomas Group, established a new powder production plant in May 2019 utilising a customised VIGA (vacuum inert gas atomisation) system.

While the company initially focused on the production of standard powder grades, with some experimentation on customised alloys, research was also undertaken on which alloys could guarantee the easiest entrance into the market for metal Additive Manufacturing powders used in highly demanding industries such as oil & gas, power generation and aerospace.

This led to the production of a number of special alloys, such as F51 together with high-carbon steels and Ni-base alloys. These materials were produced in a wide range of grades, suitable for different additive processes (BJT, PBF and DED) along with coating and HIP applications.

Duplex steel F51 is a widely used material, where the relatively high content of Cr, Mo and Ni generates improved mechanical properties when compared to austenitic stainless steel. It also offers good pitting corrosion resistance and stress cracking resistance. F53 is a highly alloyed duplex steel, referred to as a super-duplex, distinguished by its much higher corrosion resistance, making it suited to highly critical atmospheres and environments.

“Mimete’s team effort and dedication are bringing our duplex and super duplex stainless steel powder to the market. We are proud to provide our customers with high quality powders that will be used in applications where maximum performance is required.,” stated Andrea Tarabiono, Mimete’s Manufacturing Director.

Duplex and super-duplex mechanical properties are well known to the oil & gas and maritime industries. These industries are looking at Additive Manufacturing with deep interest, as it could lead to lower operating costs by streamlining production processes and developing a lean supply chain. However, the stringent qualification and process certifications can make the adoption process slow, and often more challenging than in other sectors.

By offering materials that are known to these industry sectors, it is hoped that Mimete can help to increase the adoption of Additive Manufacturing. “We believe that the opportunity to offer metal alloy powders with which customers are used to working should make the introduction of Additive Manufacturing easier in highly demanding industries,” added Tarabiono “Clearly, it is just the beginning of a long journey towards development. The call is: we all have to look beyond.”