MIM and CIM in the spotlight at Formnext 2019

December 5, 2019

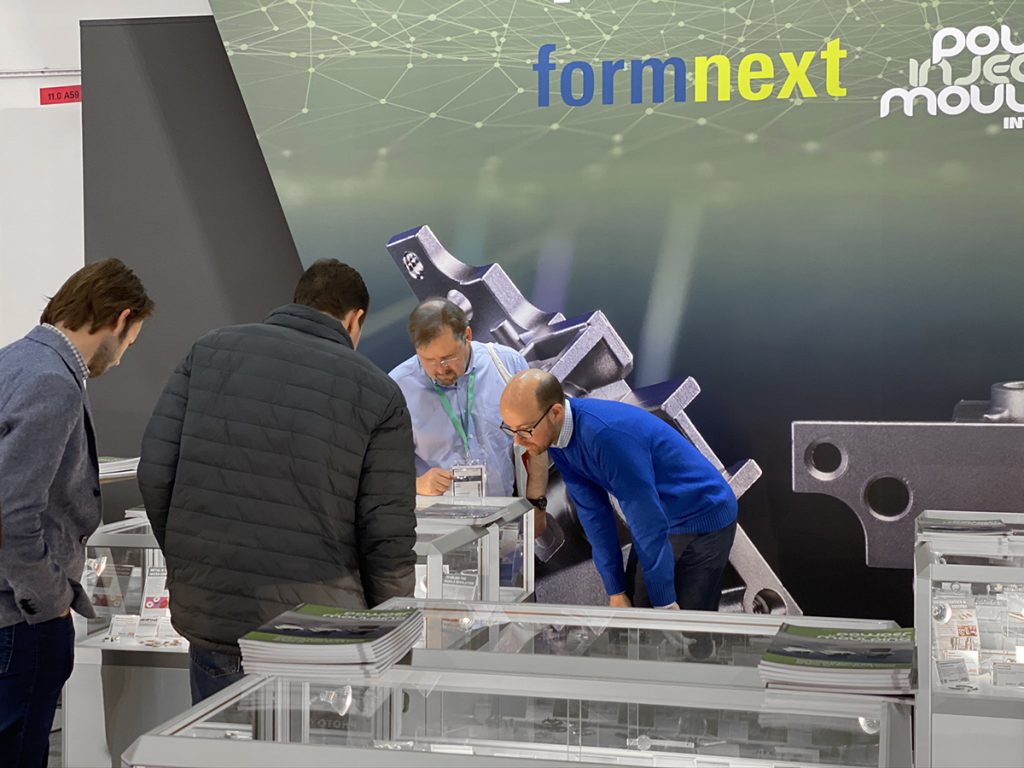

A major showcase of more than a hundred components manufactured by Metal and Ceramic Injection Moulding (MIM and CIM) was held at Formnext 2019, Frankfurt, Germany, November 19–22. Organised by PIM International in partnership with Mesago Messe Frankfurt GmbH, the 60m2 showcase put PIM technologies in the spotlight at a time when there is high interest in the potential of ‘MIM-like’ sinter-based AM technologies such as metal Binder Jetting and Fused Filament Fabrication.

The showcase featured parts from Europe, North America and Asia and included award-winning parts from the European Powder Metallurgy Association (EPMA), the Metal Powder Industries Federation (MPIF)‘s Metal Injection Molding Association (MIMA), along with numerous application examples from Germany’s MIM Expert Group (MIM Expertenkreis) and CIM Expert Group (Expertenkreis Keramikspritzguss). Dr Georg Schlieper, a regular contributor to PIM International magazine, was on-hand to speak to visitors about PIM technology and give background information to many of the applications on display.

Whilst the showcase fulfilled its purpose of increasing awareness of the use and potential of PIM, the extent to which a large number of AM-savvy visitors had no awareness of PIM, or worse, a fundamental underappreciation of the capabilities and properties of PIM parts, was surprising. It is inevitable, however, that awareness will improve as a result of MIM producers leading the drive to commercialise sinter-based AM processes as they seek to broaden the range of economically viable applications.

Beyond the PIM showcase, a number of MIM part producing companies were present in the exhibition halls, including Indo-MIM, GKN Sinter Metals, Alliance-MIM, MIMplus Technologies GmbH & Co. KG and MiMtechnik GmbH. Leading MIM-related materials and equipment suppliers were also strongly represented.