Meltio names Snowbird Technologies as sales partner

August 2, 2023

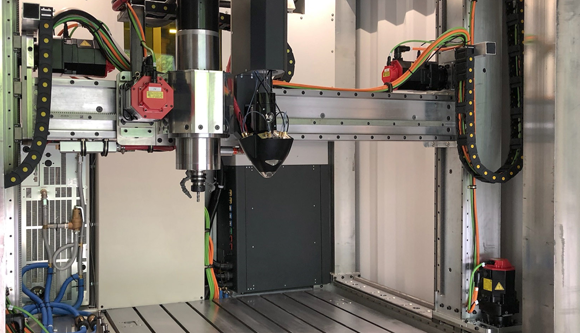

Snowbird Technologies, Jacksonville, Florida, USA, has announced that it is now a new sales partner for Meltio, Linares, Spain, a wire-laser metal Additive Manufacturing (AM) technology company based in Linares, Spain. Meltio’s Directed Energy Deposition (DED) print head is now offered as a standard component on the Snowbird Additive Mobile Manufacturing Technology platform (SAMM Tech).

“The SAMM Tech platform with Meltio components offers an impressive, high-performing solution for in-the-field parts manufacturing,” said Jeremy Heerdink, Vice President of Business Development at Snowbird Technologies. “Our goal in expanding our sales partnership of Meltio products is to provide solutions facilitating efficient and accurate Additive Manufacturing capabilities in the most remote and harshest environments around the world.”

SAMM Tech is a newly released and patented Additive Manufacturing machine that is built and operates inside a shipping container. Designed to be transportable and deployable to any location in the world, SAMM Tech aims to support soldiers and industrial operators by advancing in the-field production of large-format metal parts for equipment repairs onsite and on demand.

The Meltio head has been an integral component of the SAMM Tech platform since its inception. It was selected to be included in the standard offering due to its high performance capabilities, product quality, and integration and automation functionality.

The majority of the AM process is designed around the use of wire, which is reportedly the safest, cleanest, and easiest to work with metal feedstock. Additionally, users can manufacture dual wire for hard-facing or anti-corrosion applications. The SAMM Tech machine with the Meltio head has the the ability to additively manufacture parts in stainless steel, mild steel, carbon steel, titanium alloys, and nickel alloys, with the expectation of acting as an ideal solution for onsite manufacturing for defence, aerospace, and energy markets.

Under the sales partnership agreement, Snowbird Technologies is authorised to sell the Meltio Engine Robot (available with Dual Wire Capability) worldwide. Snowbird Technologies will also be authorised to conduct site evaluations, installations, setup and training of these Meltio products.

Download Metal AM magazine