MELD’s Additive Manufacturing technology wins at R&D 100 Awards 2018

November 17, 2018

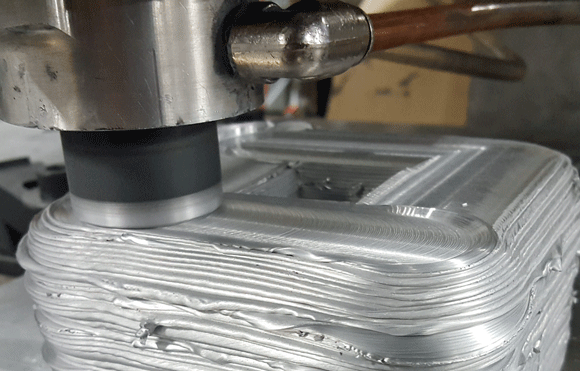

MELD is a solid-state process which can use a wide range of materials as feedstock, including metal powders and rods (Courtesy MELD Manufacturing)

MELD™ Manufacturing Corporation, Christiansburg, Virginia, USA, has been named as a winner in the R&D 100 Awards 2018 for its MELD™ Additive Manufacturing technology. Now in their 56th year, the independently judged awards honour the one-hundred most innovative technologies introduced in the past year across five major categories – Analytical/Test, IT/Electrical, Mechanical/Materials, Process/Prototyping, and Software/Services and Other.

MELD Manufacturing Corporation was launched in April 2018 as a spin-off of Aeroprobe Corporation, and holds more than a dozen patents for MELD, a solid-state process which can be used to manufacture, repair, alter and join parts using a wide range of feedstocks, including metal powders and rods. It can also be used with metal chips generated as the waste material in other manufacturing processes.

The MELD process is reported to deposit material at least ten times faster than fusion-based metal AM processes and is expected to find applications in a range of areas including the automotive, aerospace, defence and turbomachinery industries, with the company offering machine sales in addition to contract manufacturing and consulting services.

Since its launch, the technology has received the Rapid + TCT innovation award and won the SAE Create the Future Design Contest, been selected by the US Army as part of its inaugural Army Expeditionary Technology Search (xTechSearch), and been awarded funding by the USA’s Strategic Environmental Research and Development Program (SERDP) to support research into its use as a method for recycling battlefield scrap metal for repairs and manufacturing in the field.

“Our mission with MELD is to revolutionise manufacturing and enable the design and manufacture of products not previously possible,” explained Nanci Hardwick, MELD CEO. “MELD is a whole new category of AM. For example, we’re able to work with unweldable materials, operate our equipment in open-atmosphere, produce much larger parts that other additive processes, and avoid the many issues associated with melt-based technologies.”

The winners of the R&D 100 Awards were announced in a special ceremony on November 16, 2018, during the annual R&D 100 Conference at the Waldorf Astoria in Orlando, Florida.