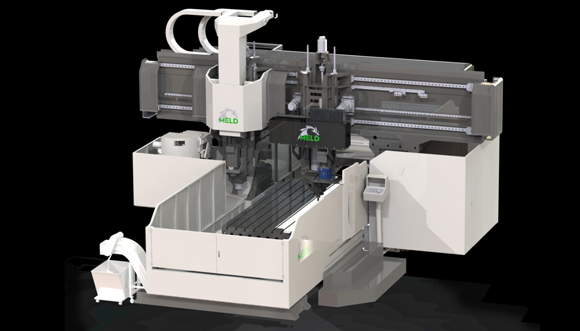

MELD unveils 3PO hybrid additive and subtractive machine

November 16, 2022

MELD Manufacturing Corporation, Christiansburg, Virginia, USA, has announced its newest machine, 3PO, at Formnext 2022. The machine features a MELD Additive Manufacturing system with an integrated subtractive head. It has a large build capacity of 4 m x 2.7 m x 1 m (10.8 m3) and eliminates the need for a separate subtractive machine.

3PO, named after Star Wars droids like the other MELD AM machines, offers a continuous Additive Manufacturing capability for large-scale parts. The subtractive capabilities include a standard 3-axis head, with an optional 5-axis head at a maximum travel speed of 12 m/minute.

MELD uses a patented Additive Manufacturing technology based on a process similar to friction welding, and can be used for the building and repair of metal components using off-the-shelf solid-state materials or powder. The process is capable of additively manufacturing large metal parts due to the fact that the it is an open-atmosphere process and not sensitive to the operating environment or material surface condition.

The MELD process can utilise various materials, such as aluminium, titanium, steel and nickel-based superalloys, and is reputedly well suited to address several challenges facing the defence sector, along with other industries.

“In response to customer demand, we’ve increased the size of parts possible with MELD, and added subtractive functionally to machine in features throughout the build,” stated Nanci Hardwick, CEO.

While 3PO is the first MELD commercial off-the-shelf hybrid machine, it’s not the first machine that the company has been involved in that includes subtractive capabilities. The MELD technology is being deployed in a machine incorporating additive and subtractive technology for the US Army’s Jointless Hull Program.

Meld is at Formnext in Hall 11.0, B41.