Magics update brings advanced traceability, connectivity and automation to Additive Manufacturing

May 3, 2023

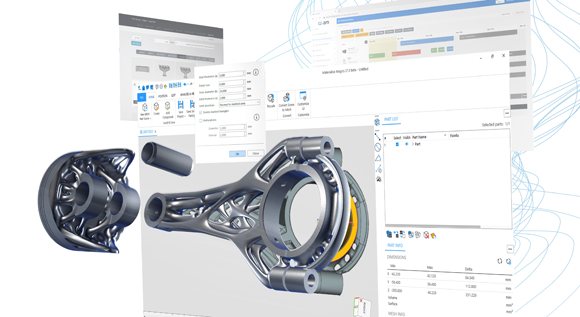

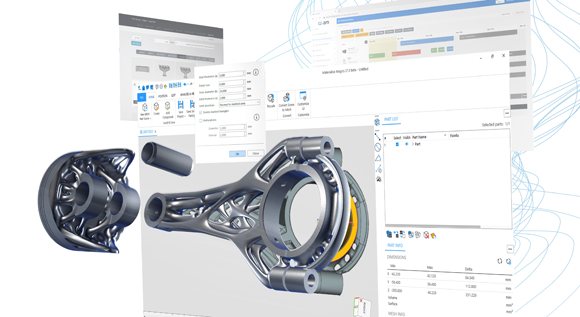

Additive Manufacturing software developer Materialise, based in Leuven, Belgium, has announced new features to Magics, its data and build preparation software. The latest update of Magics prioritises connectivity and traceability, reportedly providing a digital thread for the entire manufacturing process.

The update enables users to track part status from end to end, allowing them to see what went right and wrong in past builds, which is crucial for highly regulated industries like aerospace. Furthermore, the update introduces integration between Magics and Materialise Machine Manager, which connects users to their build processors to send project information and parameters necessary to make successful builds.

“Traceability is critical for any 3D printing production,” stated Egwin Bovyn, Product Line Manager at Materialise. “It’s not only a requirement for highly regulated industries like aerospace, but also plays an important role in quality improvement. Tracking the parameters of past builds gives users insights into what goes right and what goes wrong. It gives them a detailed log to refer to while improving their processes.”

The cloud-based solution offered by Materialise through the integration of Magics and Machine Manager allows users to share files and processing parameters with colleagues and to manage their Additive Manufacturing machine park. This stage of the workflow also has a traceability factor as all processing parameters and build files are stored in the cloud.

“By connecting Magics to our Machine Manager, we’re offering a new cloud-based solution to manage your AM machine park and connected Build Processors,” explained Brecht Pellens, Product Manager at Materialise. “Cloud-based working is inherently more collaboration friendly — users no longer need to rely on one workstation for all their build preparation work — so sharing files and processing parameters with colleagues is also easier than ever. Plus, all processing parameters and build files are now stored in the cloud, continuing the traceability factor in this stage of your workflow.”

Magics’ Workflow Automation tool offers ready-to-use and custom scripts — developed by Materialise or the user — to automate repetitive workflows during data and build preparation. Smart labelling is one such script, created for use by Protolabs, which automatically labels parts in minutes.

“Labelling twenty parts takes just one person maybe five minutes with our new automated workflow. Before, it was an hour and a half, two hours for two people. It wasn’t fun work. And now the team experiences less stress and uses their time for more challenging, interesting work that truly motivates them,” stated Christoph Erhardt, Manager of Customer Projects & Additive Design at Protolabs.

Download Metal AM magazine