LLNL offers solution to negate formation of pores in metal AM components

May 7, 2019

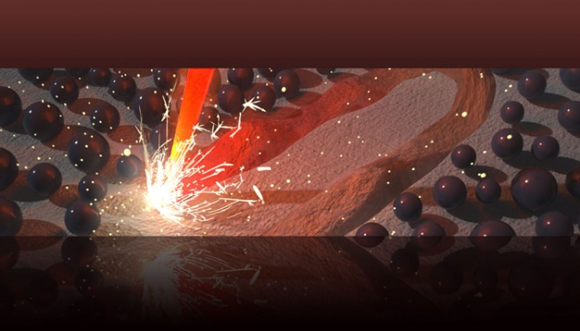

LLNL and SLAC researchers use x-ray imaging and computer simulations to prevent defects in metal additively manufactured parts (Courtesy LLNL)

Researchers based at the Lawrence Livermore National Laboratory (LLNL), California, USA, along with scientists from the SLAC National Accelerator Laboratory, California, USA, have discovered a solution to negate the formation of pores in metal additively manufactured parts.

Pores can be created under the surface of a build and lead to cracking in the finished part when under stress. The team combined high-performance computer simulations with x-ray imaging of the Laser Powder Bed Fusion (L-PBF) metal Additive Manufacturing process, obtained with SLAC’s synchrotron radiation facility, to identify a solution to the problem.

According to the team, their mitigation strategy involves reducing the power of the laser as it slows down to make turns along the complex path it takes to scan and build a metal layer. By varying the laser power throughout the build, they found they could keep the laser’s depression depth shallow and constant.

Aiden Martin, LLNL researcher and lead author on the paper, explained, “We found in a lot of parts that at the end of that area where the turnaround is, there’s a huge concentration of pores, which affect the material quality. We’ve had simulations that show this, and we needed some experimental validation. We now have a mitigation strategy where we measure the speed of the laser as it makes that turn, and we change the power dynamically during the turnaround. If we know the speed, we can adjust the power of the laser, and that keeps that depression nice and stable at the surface, and we don’t get that depression that forms the pore at the end.”

Principal investigator Ibo Matthews, Deputy Group Leader, Condensed Matter & Materials Division at LLNL, who has professionally analysed melt pool dynamics for several years, commented, “It’s been a known problem, but this is the first demonstration that we can correct it in a predictive way. Most important is the fact, the pores are always created at a distinct point in time, as the laser accelerates out of the turn. The timing is quite interesting. The assumption was that pores formed only at the deepest part of the melt pool. The fact that the pores occurred after the turn was a surprise to everybody.”

Matthews also added that the mitigation technique which the team developed, is part of a suite of tools tied to LLNL’s ‘intelligent feed-forward’ strategy which relies on simulations and model validation prior to Additive Manufacturing and is being adopted by companies in the automotive and aerospace industries. The strategy could reportedly be deployed on virtually any commercial machine by constructing power maps with a 3D slicer software that converts the parameters defined by a CAD file into system instructions.

Saad Khairallah, a computer scientist at LLNL, reportedly developed the simulation model behind the mitigation strategy using a multi-physics code called ALE3D, along with the addition of laser ray tracing which improved the fidelity of the predictions. Khairallah reported, “The way you fix the problem is adding ‘cruise control’ to your simulation. I simply told the simulation to maintain the melt pool depths constant. That fixed the problem. You don’t see pores; you don’t see keyholes. And as an added benefit, you get a power map – an output of the simulation model that indicates the power needed as a function of location along the track to prevent pore formation.”

By using a test chamber that was built at LLNL, the researchers were able to spread a single layer of powder and capture images of the laser scanning on a synchrotron beamline. Inspired by the results of the simulations and the power map, they performed experiments showing pore formations under the surface when they kept the laser’s power constant, and a consistent melt pool depth with no pores when they reduced power at the turn. The experiments were then verified by comparing them to the simulations. The team of researchers has concluded that their findings provide further insight into the L-PBF process and demonstrates the potential for science-based approaches to increase confidence in metal components produced by the process.

Martin states that he anticipates the mitigation strategy will be adopted for use by the AM industry, and added, “The pores are a real initiator of failure, like cracking and other processes that occur at the pore sites. So, if we can eliminate the pores in the part, we have a harder part and something we can ultimately certify for use. Right now, it requires additional electronics, but in the future it’s something that could probably be incorporated directly into the software. We’re hoping with some fine tuning that it can slowly be incorporated into the builds.”

LLNL reported that the next step involves incorporating the strategy into actual part builds that can involve more complex scan patterns. The researchers are interested in leveraging these methods to print lattice structures and using thermal, acoustic and tomographic methods to detect where pores begin to form in multi-layered parts.

The work was funded by the Department of Energy’s Advanced Manufacturing Office, within the Office of Energy Efficiency and Renewable Energy, Washington, D.C., USA. Ames Laboratory, Iowa, USA, also contributed to related work by completing the design of the powder feed system for in-situ x-ray characterisation during the L-PBF process and participating in the x-ray diffraction studies.

The team of researchers was made up of contributors from LLNL including Nick Calta, Jenny Wang, Phil Depond, Gabe Guss and Tony van Buuren, as well as SLAC collaborators including Anthony Fong, Vivek Thampy, Andrew Kiss, Kevin Stone, Christopher Tassone, Johanna Weker and Michael Toney. The Ames Laboratory team included Matthew Kramer and Ryan Ott.