LINK3D unveils SCHEDUL3D for Additive Manufacturing workflow optimisation

November 16, 2017

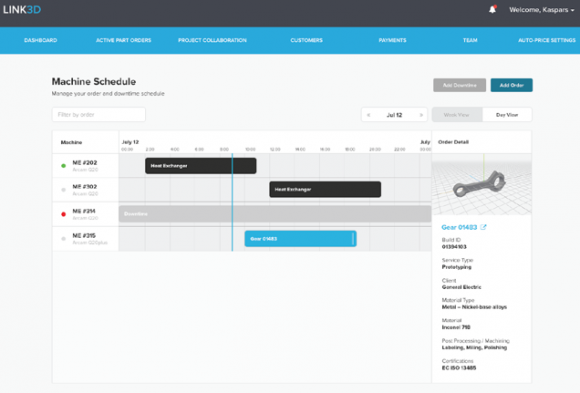

LINK3D, based in New York, USA, unveiled its latest software offering at the recent formnext 2017 exhibition in Frankfurt, Germany. SCHEDUL3D is a production scheduling tool designed to enable the most effective running of Additive Manufacturing machines. The technology will be integrated into the company’s Digital Factory workflow software.

SCHEDUL3D was designed for application engineers, facility planners, and supply chain managers to optimise their lead times, digital supply chain and better understand their machines. The technology uses AI-based algorithms to make recommendations for placing part orders on the correct and available machines to achieve real-time distributed manufacturing.

When LINK3D was launched earlier this year, Co-founders Shane Fox and Vishal Singh stated that they discovered an increasing demand for an integrated software as a service to simplify manufacturing automation. According to the company, Digital Factory was launched to connect key parts of the additive workflow, from initial product development through end production.

“SCHEDUL3D is the next step toward truly optimising and automating Additive Manufacturing”, explained Fox. “By linking software with hardware, we believe that companies will start to unlock the true potential of Additive Manufacturing as it relates to shortening supply chain and reducing our carbon footprint,” added Singh.