Link3D expands collaboration with EOS to enhance machine connectivity

November 12, 2019

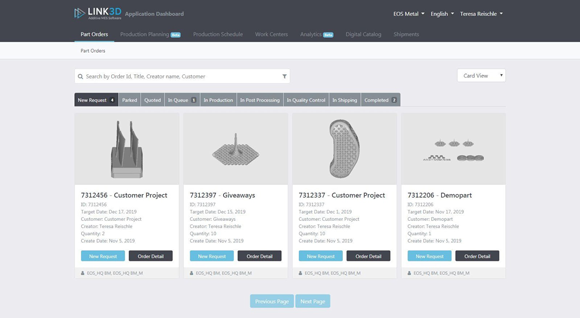

Link3D’s Additive MES Software enables users to visualise their AM workflows from order submission to delivery (Courtesy Link3D)

Additive Manufacturing execution software (MES) and workflow software developer Link3D, Boulder, Colorado, USA, is expanding its collaboration with EOS GmbH, Krailling, Germany. The collaboration began in early 2018, when EOS North America announced its implementation of Link3D’s system to enhance its clients’ customer experience.

The expanded collaboration will reportedly centralise EOS’s AM workflows globally, enabling it to track and trace in real-time all benchmark requests, scheduled jobs, machine set-up and post-production quality data across EOS sites in Krailling, as well as in Pflugerville, Texas, and Novi, Michigan, USA. With these capabilities, EOS expects to be able to review key metrics at a facility-level or on a global scale to identify opportunities that will enable new market development in cost and production management control.

“We are proud to have Link3D as one of our software partners for streamlining our facilities with AM MES & workflow software to connect the Digital Thread,” stated Patrick Schrade, Head of Application Engineering at EOS GmbH.

One of the largest financial gains to be had in AM can be achieved by maximising the productivity of the AM system. Due to the unique requirements of AM, this requires a tailored production planning system. Some challenges in designing such a system include very different build times ranging from hours to days, complex build jobs, and the impact of different AM systems and post-processing on part quality.

By combining Link3D’s MES expertise and EOS’s experience in AM, the two companies hope to address these challenges. The collaboration is expected to allow customers to tour the EOS benchmarking facilities around the globe and evaluate AM workflows to streamline EOS production, and to take advantage of EOS machine connectivity using EOSConnect, which will be integrated with Link3D’s scheduling software for real-time and in-process monitoring of the build environment for production management purposes.

This is expected to provide an excellent opportunity for EOS customers to understand how AM workflow software can be flexible to support businesses, starting with one or many EOS systems across all of its factories. Link3D’s Additive MES is said to enable users to visualise their AM workflows from order submission to delivery, connecting all sites digitally and thus improving end-to-end transparency, reducing turnaround times and offering a superior customer experience.

“Our machine connectivity program with EOS will enhance Link3D’s Production Scheduling software,” explained Vishal Singh, Co-Founder & CTO of Link3D. “With real-time monitoring, EOS customers can perform real-time capacity planning. To add, In-process monitoring integrated with a quality management systems will help businesses automate the validation of fixed workflow process requirements across EOS production systems.”

With machine connectivity, users can carry out real-time job or order monitoring through a centralised production scheduling system. This helps to identify build progress and when issues must be resolved. Organisations can also opt-in for ‘in-process monitoring’ to capture and validate workflows and quality data to meet customer regulatory requirements for AS9100, ISO9001, ITAR, SAE, EN:13485 and others.

“EOS has a rich and deep history in the Additive Manufacturing space, and Link3D is proud to have been selected as their internal workflow and MES solution,” commented Shane Fox, Co-founder and CEO of Link3D. “The collaboration will enhance Link3D’s software technology around series production for AM. Together, Link3D and EOS will deliver optimal workflow and MES capabilities to our current and future customer base.”