LINK3D brings blockchain technology to Additive Manufacturing

April 9, 2018

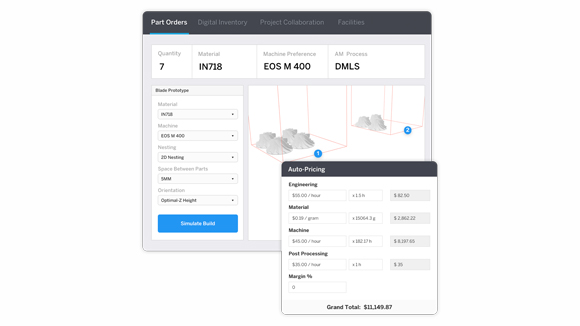

Digital Factory’s autopricing feature is one of several elements to benefit from LINK3D’s integration of blockchain technology (Courtesy LINK3D)

LINK3D, New York City, New York, USA, reports that it has integrated blockchain technology into its Digital Factory software for Additive Manufacturing. According to the company, this is the first integration of the blockchain into any AM platform.

A blockchain is a continuously growing list of records, called blocks, which are linked and secured using cryptography. Each block typically contains a cryptographic hash of the previous block, a timestamp and transaction data. The integration of blockchain technology into Digital Factory will enable:

-

data governance

-

data provenance

-

data auditability

-

and data validation.

Through the ongoing development of Digital Factory, LINK3D stated that it has found that a digital thread is crucial for the mass adoption of Additive Manufacturing. Without this digital thread, a seamless ‘strand’ of information or data to aid in the Additive Manufacturing process, from conceptualisation, to design, to production, does not exist.

Therefore, the need for file integrity and traceability is a priority for AM processes. Recordation of the digital thread for AM in a non-repudiable manner is an ideal way to avoid fraud and ensure the correct data is available for forensics during recalls. The company believes that its AM blockchain has the potential to address several major problems in the Additive Manufacturing workflow including:

- File integration, IP integrity, DRM: Blockchain technology can be used to track origination of each design file and its evolution

- Facility matching / authentication: Service bureau capability can be stored on blockchain and orders can be pre-verified

- Supply chain and logistics tracking: Once the part is shipped, the package can be tracked to ensure that it is opened by the correct parties

- Real-time data from machines: Logs from machines can be stored in an immutable way for forensics during recalls and for traceability

The exploration of blockchain (as a distributed ledger) and Additive Manufacturing, according to LINK3D, is untested and could provide a solution to organising data in a high-level, safe way across the AM workflow. Vishal Singh, LINK3D’s CTO and Co-founder, stated, “Blockchain technology can be utilised as the backbone technology in the digital manufacturing ecosystem. Our technology is the first of its kind and will absolutely simplify and secure 3D printing processes for all industries.”