Linde to showcase new gas technologies for improving metal Additive Manufacturing quality

April 3, 2018

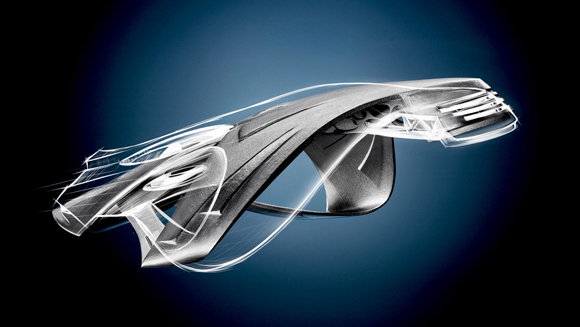

A metal additively manufactured structure produced with the aid of Linde gas technologies (Courtesy Linde LLC)

Linde LLC, Bridgewater, New Jersey, USA, is to showcase three new technologies to improve the quality of metal additively manufactured parts at this year’s Rapid+TCT 2018 in Fort Worth, Texas, April 24-26. The new gas-based technologies offer solutions to issues around the storage of metal powders, monitoring of the AM process and final surface quality.

High-end Additive Manufacturing is said to depend not only on the incoming quality of metal powders but also on storage conditions of sensitive powder metals such as aluminium or titanium alloys before use. Linde’s ADDvance® powder cabinet purges the storage atmosphere with inert gas, while tightly controlling temperature and humidity.

The company’s ADDvance O2 precision atmosphere monitoring system is a portable unit which precisely controls oxygen and humidity levels by continuously analysing the powder chamber atmosphere. This can prevent unwanted gases from entering the AM build chamber through insufficiently purged or contaminated metal powder.

To remove surface oxides, unfused powders, or other residues from AM parts prior to further processing or surface finishing, Linde has developed its ADDvance Cryoclean technology. The cleaning system uses CO2 snow plus blasting abrasives to cost-effectively remove difficult residues from AM parts without the use of water.

Grzegorz Moroz, Program Manager, Metals, Linde, explained, “Reproducible quality is the ultimate goal of Additive Manufacturing. Variations in processes and materials can impact part quality and performance, so Linde works with manufacturers of aerospace, automotive and medical components to reduce or eliminate variations at every step. These industries demand documented consistency in AM processes, and Linde offers gas-based technologies and know-how to help meet strict quality requirements.”

Linde opened a global Additive Manufacturing R&D centre near Munich, Germany, in 2016, and collaborates with universities and manufacturers, including Airbus Group Innovations, to improve AM processes. The company’s Munich R&D lab is currently said to be focusing on the effect of atmospheric gases and gas mixtures on metal powders to optimise layering processes during Additive Manufacturing.

RAPID + TCT 2018 will run from April 23-26 in Fort Worth, Texas, USA.