Linde launches gas for optimal sintering in the Desktop Metal Studio System

September 21, 2020

Linde, a global industrial gas specialist headquartered in Guildford, Surrey, UK, has launched ADDvance® Sinter250, a new gas mixture to deliver optimal atmospheric conditions in sintering furnaces as part of Desktop Metal’s Additive Manufacturing process.

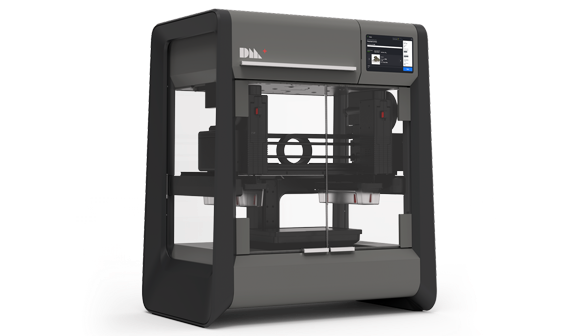

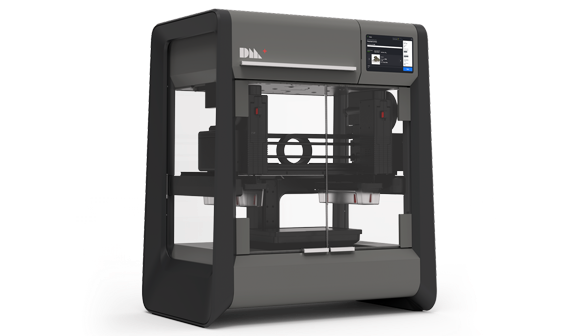

The argon/hydrogen gas mixture has reportedly been developed for Desktop Metal’s European customers, for use with the company’s Studio System™.

Linde states that it will also supply customised installation kits to simplify the implementation of the Studio System, allowing for faster start times, as well as consultancy services to advise on gas supply options and best practice for cylinder storage.

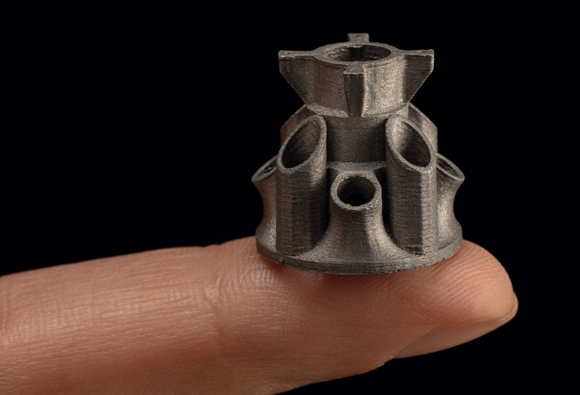

According to Linde, the tailored argon/hydrogen mix of ADDvance Sinter250 is for use on parts made from stainless steel powders, but the company states that it will also supply a pure argon 5.0 gas for the manufacture of parts made from low alloy steel and tool steel powders.

“Linde has long been a pioneer in the development of innovative gas mixtures to optimise manufacturing processes,” stated Pierre Forêt, senior expert Additive Manufacturing, Linde. “In this rapidly developing world of Additive Manufacturing, we are delighted to be collaborating with an innovator in the space such as Desktop Metal to supply this gas mixture to their customers.”

Arjun Aggarwal, VP of Business Development & Product, Desktop Metal, commented, “Linde has developed a standard gas offering optimised for Studio System and is able to offer this streamlined solution to our European Desktop Metal customers.”

Aggarwal added, “This enables us to expand our horizons and bring added value to our business.”