Latest version of Siemens NX expands toolset for digitalising the machine shop

November 23, 2017

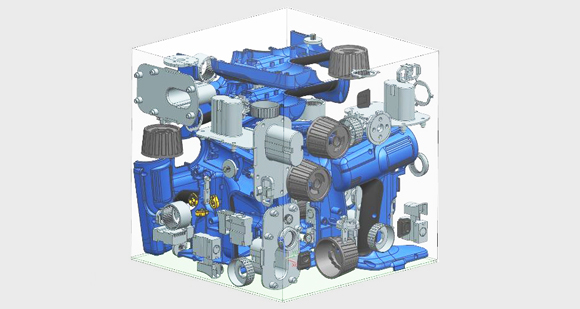

Siemens NX allows multiple parts to be nested in the build area of an AM system to optimise efficiency (Courtesy Siemens)

Siemens has released the latest version of its NX™ software, which incorporates tools for Additive Manufacturing, CNC machining, robotics and quality inspection. The updated software is reportedly designed to enable the digitalisation of part manufacturing within a single, integrated end-to-end system.

The software is said to offer advanced automation capabilities for computer-aided manufacturing (CAM), including robotic programming, adaptive milling and tooling design and to provide industry-specific technology to help deliver high-quality products to the market in less time. In addition, the NX Machining Line Planner tool, combined with integrated NX CAM software, provides new capabilities for industries with high-volume production of complicated parts, such as automotive and industrial machinery.

Siemens stated that it designed the new version of NX in response to the added pressure part manufacturers now face from changing market expectations, with many customers requiring improved accuracy and faster response times. In order to remain competitive, Siemens said, many part manufacturers look to digitalisation to connect all of the steps of part manufacturing, planning and production with a single source of information, or a ‘digital thread’.

Machine shops need to offer Additive Manufacturing combined with a highly automated process chain that digitally connects design, print preparation, NC and quality inspection programming to production…”

The company believes that implementing a digital strategy can enable part manufacturers of all sizes to take greater advantage of automation, adopt Additive Manufacturing for production and ultimately expand into new market opportunities and reduce time to delivery.

“In order to grow their businesses and expand into highly competitive markets like the aerospace and semiconductor industries, machine shops need to offer Additive Manufacturing combined with a highly automated process chain that digitally connects design, print preparation, NC and quality inspection programming to production,” explained Christoph Hauck, Managing Director of New Technologies and New Markets, MBFZ toolcraft GmbH, an early adopter of Siemens’ AM technology.

“Siemens offers all of these capabilities in one complete and integrated system for part manufacturing. This allows us to link each step in our digital process chain, providing critical process control, associative data flow and traceability – which are important for our customers,” he concluded.

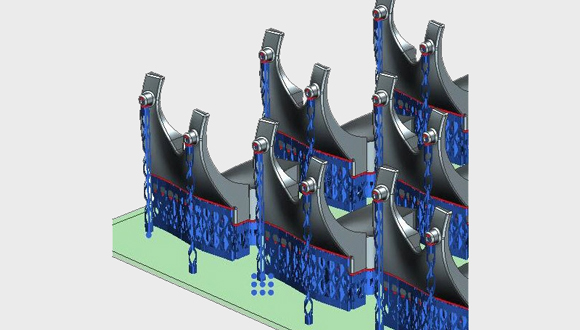

Siemens NX can automatically create various support structure types for use with powder bed AM systems (Courtesy Siemens)

The new version of NX also incorporates automation enhancements aimed at expanding production efficiency and reducing cost. The software’s robotic programming technology provides the ability to automate complete manufacturing cells, including programming robots to perform machining and pick-and-place operations. In addition, it now offers adaptive milling and tube milling capabilities, enabling users to automate CNC machine programming and accelerate the cutting of complex parts.

“Transformative technologies like Additive Manufacturing and advanced robotics offer tremendous potential for manufacturers of all sizes to gain an advantage in today’s competitive market,” stated Zvi Feuer, Senior Vice President of Manufacturing Engineering Software for Siemens PLM Software. “NX provides a fully integrated solution for part manufacturers to utilise these powerful technologies, creating the ability to improve overall business performance and helping to create a truly digital machine shop.”

Siemens also develops applications for Additive Manufacturing process simulation in Simcenter 3D, a tool designed to help manufacturers industrialise AM by manufacturing components ‘first-time-right’.