Large-scale steam turbine blades additively manufactured at ORNL

December 19, 2023

Researchers at the US Department of Energy’s (DOE) Oak Ridge National Laboratory (ORNL) in Tennessee, USA, have used wire arc Directed Energy Deposition (DED) to additively manufacture large rotating steam turbine blades used in power plants. Collaborating with Siemens Technology, the US research and development division of Siemens AG, the project is said to demonstrate the viability of this technology for the scalable production of critical components.

“There’s now a realisation that we cannot get low-volume castings and forgings that exceed 100 or 200 pounds [45 – 90 kg] from the domestic supply chain,” said Michael Kirka, lead research and group leader for the Deposition Science and Technology group at ORNL. “It’s put us in an untenable position, especially as we see how international conflicts have affected the international movement of critical supplies.”

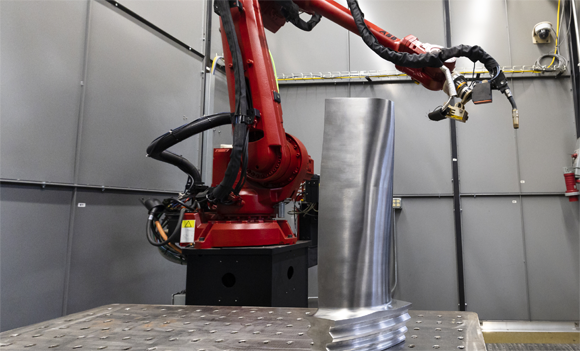

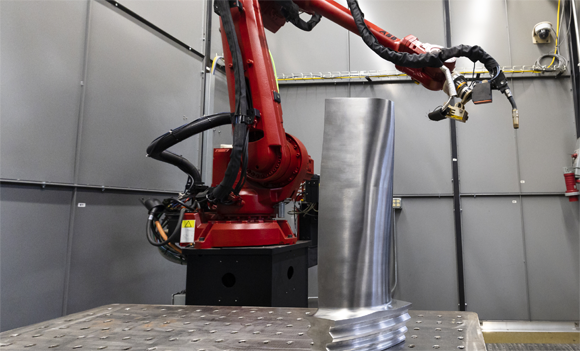

ORNL’s wire arc Additive Manufacturing employs an electric arc to melt metal wire, a process managed by a robotic arm. It gradually constructs thin layers of metal to achieve the desired shape. After manufacturing, the part undergoes machining to fulfill the final design specifications. The wire-arc technology, utilised in manufacturing the turbine blade, was developed in partnership with Lincoln Electric under a cooperative research and development agreement.

Because this wire arc manufacturing method is based on welding technology, it can be used for repairing existing parts. This could allow companies like Siemens Energy, a Siemens sister company that is also a partner in the project, to more easily maintain and upgrade equipment under service contracts with electric utilities.

When the Siemens wire arc research began in 2019, it focused on component repair. However, the scope expanded during the COVID-19 pandemic, when the wait for new cast steam turbine blades stretched to two years. Then the project broadened to include manufacturing entire replacement parts, because these types of turbine engines are versatile enough to be used in gas, coal and nuclear power plants, Kirka shared.

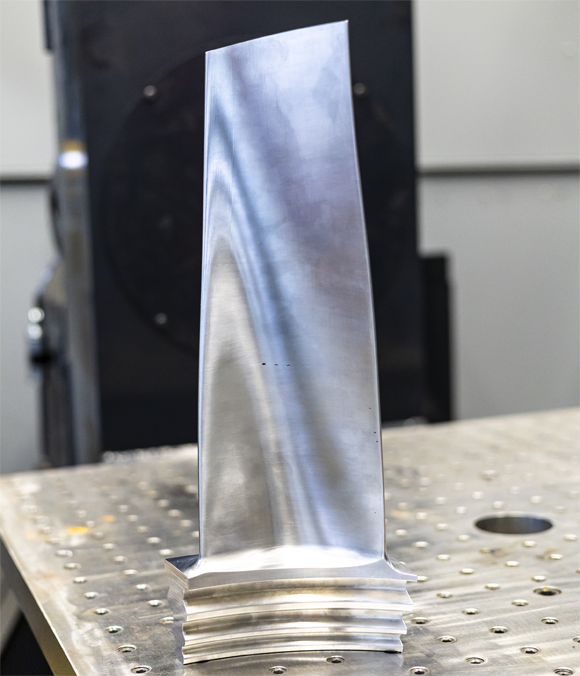

Researchers at ORNL experimented with different materials to develop improved methods of evaluating the mechanical performance of parts manufactured additively. The large steam turbine blade, made from a steel alloy, was the result of these efforts.

“The original intent was to just print 25% of the top section of the blade,” stated Anand Kulkarni, senior principal key expert for Siemens Technology. “But when we saw the potential of the wire arc setup at ORNL, we thought we could do the whole blade in one build. The capability to scan the part while it was being built gave us the right information that could be fed to our machining staff and enabled us to reduce production time.”

While the wait for large castings and forgings has decreased to seven or eight months, ORNL was able to manufacture the blade in just12 hours. Including machining, a blade can be finished in two weeks, Kulkarni said.

Although wire arc is a prominent AM technology, it had not previously been used to make a rotating component of this scale, Kirka added. Turbine blades typically have no parallel or perpendicular surfaces. Its contoured curves narrow towards the tip. “Being able to print and finish something with no locating features is a challenge,” he said. In addition, heavier parts of this size cool more slowly, adding sensitivity to the speed and order of depositing the layers.

After machining the part, Siemens is working with the Electric Power Research Institute on non-destructive evaluation and testing. “We’re still looking at the properties side of things to see how results compare with traditional methods,” Kulkarni added. However, for repairs, the properties don’t need to be identical. The current challenge is keeping engines running and avoiding downtime, he said.

“But if the quality of the part is good, that opens doors to more on-demand manufacturing,” Kulkarni commented. “And this case study opens the envelope to large components.”

A key advantage to Additive Manufacturing is that it frees companies from dependence on specific manufacturing tools they don’t control, such as moulds made by a single casting house for a single design. Many of the large-scale components in today’s turbines are several decades old, but because of closures and industry offshoring, the tools that created them have effectively disappeared, Kirka added. Additive Manufacturing offers a more reliable alternative because it can replicate any design.

Other ORNL researchers who contributed to the project include Ryan Duncan, Luke Meyer, Chris Masuo, Chris Ledford, Patxi Fernandez-Zelaia, Andrzej Nycz, Sarah Graham, and Andres Marquez Rossy. The project was funded by the DOE Office of Fossil Energy and Carbon Management.

The steam turbine blade was manufactured in DOEs Manufacturing Demonstration Facility. The MDF, supported by DOE’s Advanced Materials and Manufacturing Technologies Office, is a nationwide consortium of collaborators working with ORNL to innovate and catalyse the transformation of US manufacturing.

Download Metal AM magazine