L3Harris launches Additive Manufacturing materials investigation on latest SpaceX flight

March 17, 2023

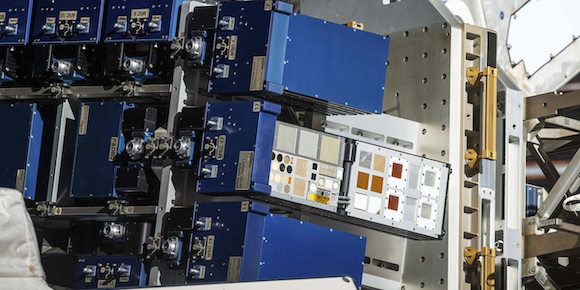

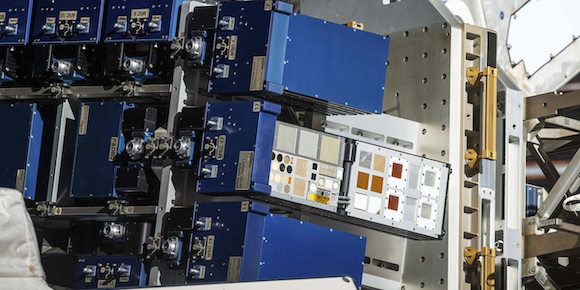

L3Harris Technologies, Melbourne, Florida, USA, aims to leverage the International Space Station (ISS) National Laboratory in its search for durable materials to additively manufacture satellite components. Among the payloads launched on SpaceX’s 27th Commercial Resupply Services (CRS) mission is a project to test an L3Harris-designed, additively manufactured radio frequency (RF) circuit and various AM material samples.

Before AM materials can be used to build more sustainable and efficient parts for spacecraft, they must be tested to ensure they can withstand the harsh environment of low Earth orbit (LEO). The project is a continuation of 2021 experiment which collected two months of data on AM RF circuits. This time, L3Harris will also test photonic material for a new technology called photonic integrated circuits. Used for satellite communications and similar to computer chips, these circuits utilise light instead of electrons in conventional electronics, similar to how light carries information in fibre-optic cables for phone and internet data.

“We’re excited to test the 3D printed materials for six months and compare the new results with previous ISS experiments and ground tests,” stated Arthur Paolella, senior scientist and technical fellow with L3Harris. “The ability to 3D print materials for use in space opens up new possibilities for satellite design and construction while making spacecraft manufacturing more cost-effective and efficient.”

Eduardo Rojas, director of the Wireless Devices and Electromagnetics Laboratory at Embry Riddle Aeronautical University, Daytona Beach, Florida, and his students are assisting with the experiment. The investigation will utilise the MISSE Flight Facility (owned and operated by ISS National Lab Commercial Service Provider Aegis Aerospace) mounted to the exterior of the ISS. There, the material samples will experience the harshness of space and will be subjected to various conditions, including extreme temperatures and radiation, to validate their performance in the same environment where the satellites will operate.

“While we can test the durability of these materials on Earth against one or two of these factors at a time, on the ISS, we can test every potential hazard – and all at once,” Paolella added.

The results are expected to be used to develop and refine the materials to incorporate them into satellite manufacturing. Paolella suggested that photonic integrated circuits for optical communications between satellites and the ground could one day reduce the size, weight, and power of communications systems and increase the amount of data possible to transmit from satellite to satellite.

L3Harris stated it will continue to explore other potential space-based applications for additively manufactured materials, including in-orbit manufacturing and repair.

Download Metal AM magazine