Japan’s SLIM lands on Moon with help from metal Additive Manufacturing

January 25, 2024

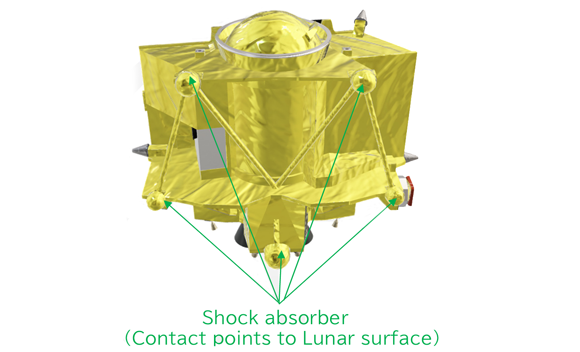

The Japan Aerospace Exploration Agency (JAXA)’s Smart Lander for Investigating Moon (SLIM) has landed on the moon, making Japan only the fifth nation to successfully reach the lunar surface. Playing an essential role in protecting the spacecraft from the impact of the lunar landing, metal Additive Manufacturing was used to produce the shock absorber structures found on the tip of each leg.

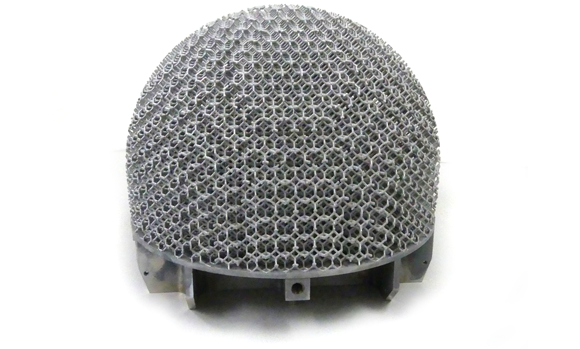

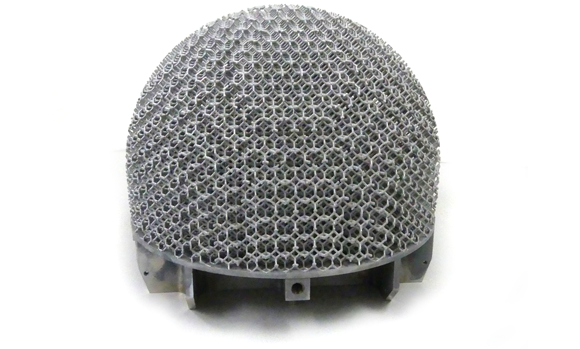

Made by Japan Additive Manufacturing Co (JAMPT), based in Yamagata, the aluminium lattice, sponge-like structure has a hemispherical shape that is designed to crush on landing, thus softening the impact.

The SLIM was mounted on the H-IIA Launch Vehicle No. 47 (H-IIA-F47), which was launched from the Tanegashima Space Center on September 7, 2023. It landed on the moon on January 20, 2024, and demonstrated that its pinpoint landing technology necessary for future lunar probes was a success, with the touchdown being within 100 m of its target.

“We proved that you can land wherever you want, rather than where you are able to,” stated Shinichiro Sakai, project manager for the lander, during a press conference. “This will inspire more and more people, desirably Japanese missions, to try to land on unexplored places on the moon.”

Established in 2017 by Sojitz Corporation and Koiwai Co Ltd, JAMPT claims to be the first service bureau in Japan capable of providing comprehensive services in the field of metal AM, handling everything from powder development and manufacture to prototyping and production. The company has Laser Beam Powder Bed Fusion (PBF-LB) machines from EOS and Concept Laser, Electron Beam Powder Bed Fusion (PBF-EB) machines from Arcam, and a laser Directed Energy Deposition (DED) machine from Optomec. It operates in-house metal powder production, with a Plasma Rotating Electrode Process (PREP) atomiser.

Download Metal AM magazine