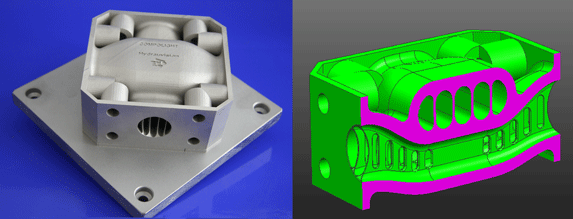

CASE STUDY: Hydraulic crossing

This case study demonstrates the increased performance possible using AM techniques. Here Selective Laser Melting (SLM) allowed designers to realise significant increases in performance in hydraulics by exploiting the possibilities of this Additive Manufacturing process.

Inside the hydraulic crossing two fluid streams cross within a limited space without mixing. The conventionally produced part consists of a massive metal block where drilled and locked blind holes meet in two levels. The main bore splits into two smaller bores to keep the height and the possible mass flow constant. The weight of the conventionally produced pipe crossing is 20 kg and measures 230 x 230 x 50 mm.

Without being hindered by the limits of conventional production processes, the designer was free to optimise the functionality and in the AM produced hydraulic crossing the fluid flow was improved by adapting the internal channel geometry according to flow simulation results. Geometrical changes of cross section profiles can be manufactured without great effort.

fig17 An additively manufactured hydraulic crossing (left) with the internal channel geometry shown (right). Designed during EU-funded project CompoLight; built on an EOS M270 system at Fraunhofer IFAM

Concerning thermodynamics, fins inside the channels are feasible to improve thermal exchange processes and to increase the parts stiffness at the same time. The newly designed hydraulic crossing (above) was produced from a stainless steel material, with internal fins supporting the part during processing. The new components dimensions are 80 x 80 x 50 mm and the total weight is only 0.7 kg, resulting in a mass reduction of around 96%.

Comparison of pressure loss of conventionally and additively built hydraulic crossing

In this study the optimisation of the channel geometry has an enormous impact on the crossing’s performance and thus on the entire hydraulic system. At a mass flow of 100 l/min, the pressure loss of the new design is reduced to only 20% of the pressure loss of the conventionally designed and manufactured part. Additionally, without any post-processing the surface quality of the AM part was sufficient to be flanged to the connecting piping. Even at a test pressure of 1400 bar, the part showed neither plastic deformation nor leakage.