Industrial AM acquires RoboWAAM Advanced from WAAM3D

November 7, 2023

WAAM3D, based in Milton Keynes, UK, has announced the sale of a RoboWAAM Advanced to Industrial AM, a manufacturer of metal components located in Mo i Rana, Norway. With this sale, the total number of Directed Energy Deposition (DED) Additive Manufacturing machines now sold by WAAM3D has increased to nineteen, with customers located in ten different countries.

Industrial AM is owned by MOMEK Robotics, Testpartner and Kunnskapsparken Helgeland and works with petroleum, process and mineral industry, aquaculture, and power industry customers to deliver more sustainably produced large-scale metal components.

“We are delighted to work with Industrial AM and be their first choice for large scale metal AM capabilities,” commented Dr Filomeno Martina, CEO and co-founder of WAAM3D. “Their use cases are incredibly varied and interesting, and the Norwegian market is an exciting one. The incredible wealth of experience in related technologies brought by Industrial AM and their backers matches perfectly with our pursuit here at WAAM3D for non-stop innovation. We look forward to working with them on industrial projects with real end-use applications.”

Thomas Borgen at Industrial AM added, “We are excited to be collaborating with WAAM3D. The purchase of their RoboWAAM Advanced platform will be game-changing for our work with world leading clients in the oil and gas, process and mineral, aquaculture, and renewables industries. We are very pleased to be a pioneer in the growing industry of large-scale 3D metal printing here in Norway and with WAAM3D we are buying not just a machine, but the company’s leading-edge processes and expertise as well.”

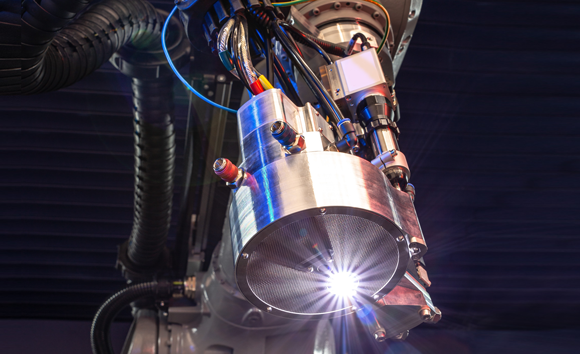

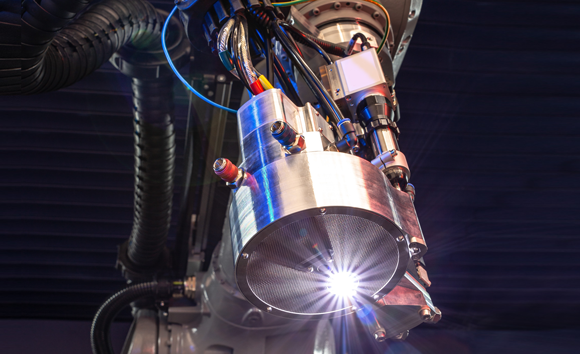

RoboWAAM Advanced was launch in April 2022, and continues to be developed. The latest features highlighted by WAAM3D include:

- Real time ShapeTech – a brand-new interferometric sensor which reconstructs the 3D profile of the deposited structure, extracting the layer height value all around the component. It gives immediate confidence in the consistency of deposition and in the achievement of key geometrical targets, whilst manufacturing is in progress, eliminating the need for lengthy laser scans or touch-probe quality checks

- Double-point temperature measurement capability – leading the deposition to ensure consistent build conditions; and trailing the deposition for in-process parameters checks

- Electronic wire positioning for increased process stability

- Dual wire feeder for increased deposition rates

- Fume Management System (FMS) with onboard fume confinement, filtration, and treatment

- Global shielding for deposition of reactive materials with fully automatic purging, atmosphere maintenance, and evacuation cycles, with the alternative of a new local shielding option for out-of-chamber deposition

- Process camera for remote melt-pool imaging, combined with CCTV for safe machine supervision

- Bulk wire storage and large spool capability (70 kg), for longer uptimes and reduced operator’s intervention

- Standalone plug-and-play installation with full health and safety compliance

Industrial AM has also chosen the full suite of WAAM3D’s software, including:

- WAAMPlanner which turns a parts pre-form into executable RoboWAAM code. It includes planar and non-planar slicing, 2D and 3D sectioning, and layer grouping. It is capable of best-in-class tool-path-planning with dedicated AM approaches and multi-material and multi-process capability

- WAAMKeys, which eliminates defects and keeps the layer height under control. It carries out automatic parameter calculations, with advanced thermal compensation modules to achieve a target layer height, regardless of changes in geometrical features

- WAAMSim, which visualises RoboWAAM’s deposition environment. It includes a virtual, gaming-inspired environment for collision detection and offline tool-path-plan validation

- WAAMCtrl, an all-encompassing operating system for RoboWAAM. It incorporates an operator’s dashboard, the component’s digital twin, interactive data navigation, and historical database with complete manufacturing process record (parameter by parameter, including all dependent variables such as temperature and shape), integrated onto WAAM3D’s hardware and sensors

WAAM3D is now exhibiting at Formnext 2023 at Hall 11.0, B79.

Download Metal AM magazine