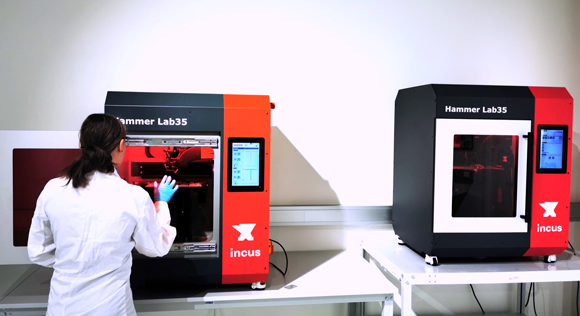

Incus Hammer Lab35 metal AM machine in production

January 14, 2021

Incus GmbH, Vienna, Austria, has begun production of its Hammer Lab35 metal Additive Manufacturing machine. The lithography-based metal manufacturing (LMM) process, defined as a vat photopolymerisation process (VPP) by ISO/ASTM, has been developed by Incus to offer an economic method for developing prototypes and small-scale production of components in Metal Injection Moulding (MIM) quality.

The Hammer Lab35 was launched at Formnext 2019, shipping its first series Hammer Lab35 machine in March 2020 and continuing to grow its network of customers and partners throughout 2020.

With a print speed of up to 100 cm3/h and a lateral resolution of 35 µm, the Hammer Lab35 is designed to deliver high-quality parts. The process can also be integrated into existing MIM production lines or research and development departments as an option for small-scale production and prototyping.

Two Hammer Lab35 machines are reported to already be in operation at the Institute for Precious and Technology Metals at Pforzheim University and its spin-off company, Metshape. Within this cooperation, the process and system are reviewed and tested, and new materials and applications are being developed.

“Despite this challenging year, we had great collaborations with customers and have proven that LMM has the potential to increase performance and to reduce costs for small and mid-scale production, as well as for manufacturing parts featuring complex geometries,” stated Dr Gerald Mitteramskogler, Incus CEO.

“Our team is extremely proud to have added 3D printing of metals with lithography to the manufacturing landscape. We highly appreciate the trust and patience of our first customers that have been helping to develop our product and our company,” continued Mitteramskogler. “We still have a journey ahead to scale up to mass-production, but we are eager to continue this path in 2021.”