Huisman and RAMLAB to produce ‘world’s heaviest’ wire-arc additively manufactured crane hook

June 20, 2018

A 400 mt offshore mast crane aboard a subsea vessel (Courtesy Huisman Equipment)

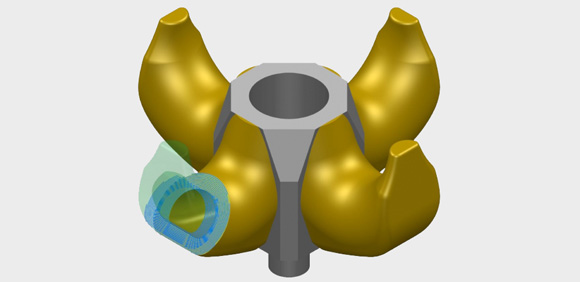

Netherlands-based companies Huisman Equipment, Schiedam, and Rotterdam Additive Manufacturing Lab (RAMLAB), Rotterdam, have initiated a project to produce a large offshore crane hook using Wire & Arc Additive Manufacturing (WAAM). The hook, which is based on a Huisman 4-prong hook design, will reportedly take advantage of the weight and material savings offered by metal Additive Manufacturing by incorporating a hollow design.

The final product is expected to measure over 1 x 1 m and weigh close to 1000 kg, making it what is thought to be the world’s largest steel additively manufactured structure in terms of weight. It will have a Safe Working Load (SWL) of 325 mt, significantly higher than that of a previous WAAM offshore crane hook successfully load tested by Huisman in January 2018, which was said to have a SWL of 80mt.

CAD design for the planned crane hook, expected to measure over 1 x 1 m and weigh close to 1000 kg (Courtesy Huisman Equipment)

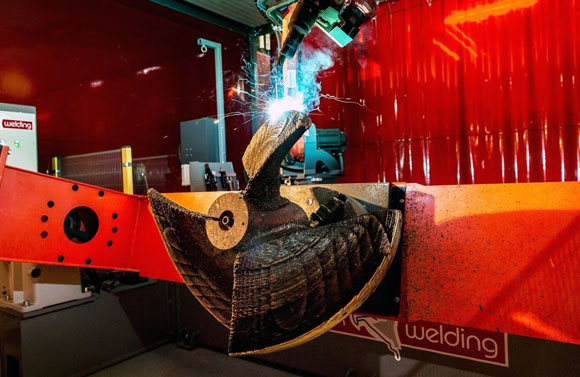

RAMLAB is thought to be the first laboratory focused specifically on Additive Manufacturing offshore and marine applications. The laboratory was initiated by the Port of Rotterdam Authority, InnovationQuarter and RDM Makerspace and, in 2017, produced the world’s first additively manufactured ship propeller: the 1,350 mm diameter, 400 kg, triple-bladed WAAMpeller. RAMLAB was recently awarded the Manufacturing Leadership Council’s Engineering and Production Technology Leadership Award 2018.

The WAAMpeller during production at RAMLAB, Rotterdam (Courtesy RAMLAB)

By producing a class-certified offshore crane hook using WAAM, Huisman and RAMLAB stated that their goal is to advance common rules and guidelines for the use of WAAM in offshore/maritime engineering.

DNV GL, Bureau Veritas and ABS, three of the leading classification societies for the maritime and offshore industry, are also said to have joined the project, enabling the WAAM offshore crane hook to receive triple certification following its production and successful testing, marking a significant step in the adoption of rules for the AM of structures for the maritime and offshore industry.

In addition, voestalpine Böhler Welding will provide feedstock and materials expertise for the project, while Autodesk will provide support by means of its Additive Manufacturing software.