HRE introduces its second generation additively manufactured titanium wheel

May 23, 2019

The second generation HRE3D+ wheel on a 2019 Ford GT (Courtesy HRE Performance Wheels)

HRE Performance Wheels, headquartered in Vista, California, USA, unveiled the second generation of its additively manufactured HRE3D+ titanium wheels at this year’s Rapid + TCT show, Detroit, Michigan, USA, from May 20–23. To further improve the HRE3D+ concept, the company once gain collaborated with GE Additive to utilise multiple Additive Manufacturing systems in its development.

The company reports that in addition to a futuristic design, which it states is impossible to create with traditional manufacturing systems, the second generation HRE3D+ revolutionises the wheel manufacturing process by reducing overall material waste from around 80% to 5%.

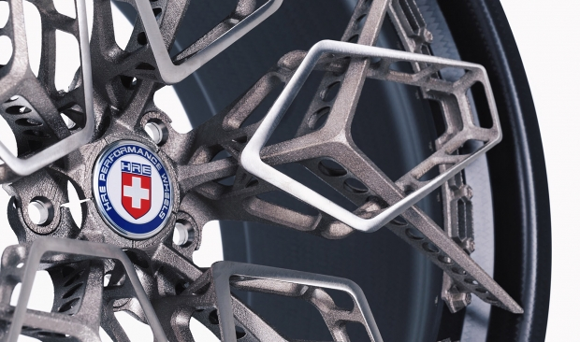

A redesigned centre area has reduced the overall part count to just five additively manufactured sections (Courtesy HRE Performance Wheels)

The latest HRE3D+ wheel is also reported to be significantly lighter, with the 20 and 21-inch wheels of the first generation weighing 20 and 23 pounds respectively, while the more advanced design of the second generation allows for a total wheel weight of only 16 and 19 pounds for the same size wheels. The first HRE3D+ concept comprised of six parts, including a centre cap and lug seat section holding the spokes against the vehicle. The company states that it further reduced the weight for the second generation wheel by redesigning the centre area to reduce the part count to just five additively manufactured sections.

According to HRE, its experience of working with AM has prompted significant refinements in the technique which has opened up possibilities for future advancement, including the Additive Manufacturing of one-piece wheel centres. During the Rapid event, the company unveiled the second generation of the HRE3D+ wheel on a 2019 Ford GT in GE Additive’s booth.

Alan Peltier, President/CEO of HRE, stated, “We’re proud to be breaking new ground in wheel manufacturing with the updated HRE3D+ wheels. Working with GE Additive have given us access to some truly cutting-edge technology, and we’re exploring the future of wheel technology together with tools that will continue to evolve over the next few years. We can’t wait to see what we’re able to accomplish next.”

www.hrewheels.com | www.ge.com/additive