Höganäs extends its Digital Metal technology to enable titanium Additive Manufacturing

July 19, 2017

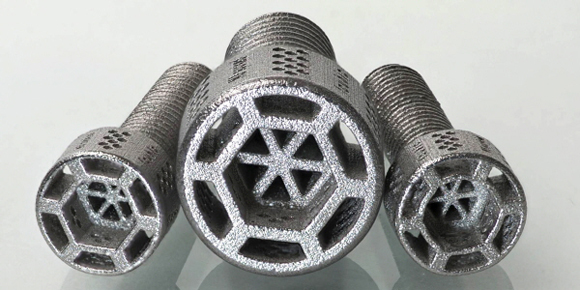

Aerospace parts produced using Digital Metal AM (Courtesy Höganäs)

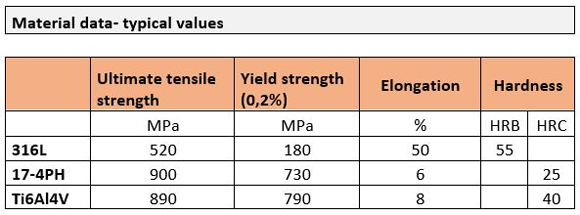

Sweden’s Höganäs AB has further extended the range of materials that can be used with its Digital Metal Additive Manufacturing technology to include titanium. Ti6Al4V will now be offered in addition to Stainless 316L and 17-4PH, the latter of which was added in April 2016.

Ti6Al4V is widely used in the Additive Manufacturing industry. It combines high strength, high hardness and ductility with high corrosion resistance and offers a 45% weight reduction compared to conventional steels. According to Digital Metal, Ti6Al4V meets ISO 22068.

Digital Metal is a metal Additive Manufacturing technology which enables the production of small and complex objects that would be costly, if not impossible, to produce using traditional methods.