HBD’s metal Additive Manufacturing improves mold cooling efficiency for household appliance company

March 25, 2024

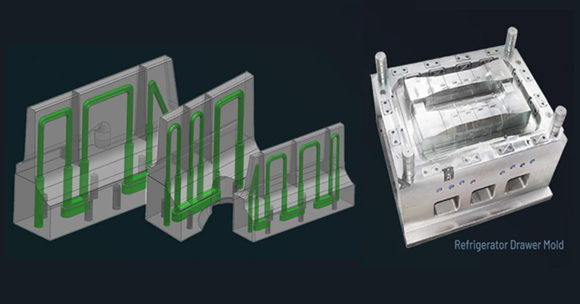

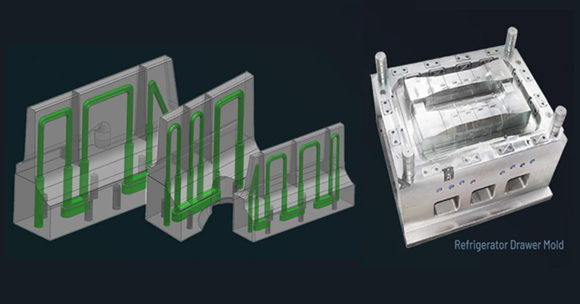

Shanghai Hanbang 3D Tech Co., Ltd. (HBD) has reported on a recent collaboration to bring conformal cooling mold technology to a manufacturer of refrigerator components. Working with the mold manufacturer, metal Additive Manufacturing was used to produce three optimised mold inserts with internal cooling channels for its customer.

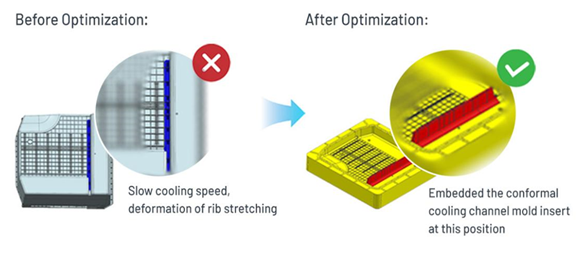

The customer, a household appliance company, had experienced problems with the production of rib components used inside the refrigerator drawer. The cooling cycle for the mold used to produce these parts lasted around seventy seconds, which led to the deformation of the rib and hindered efficient large-scale production.

To solve this issue, the mold manufacturer proposed the use of metal Additive Manufacturing to enable the inclusion of intricate conformal cooling channels.

Traditional machining methods have limitations in the design and location of cooling channels in the mold, whereas metal Additive Manufacturing can be used to precisely build internal channels exactly where needed. This improves cooling, reduces molding cycle time, and enhances product quality.

Following discussions between HBD and the mould manufacturer, it was decided to use the HBD 350 Metal AM machine to produce the mold inserts with internal conformal cooling channels. The three additively manufactured inserts measured 188 X 24 X 52 mm, 112 X 24 X 52 mm, and 192 X 24 X 52 mm and were added to the original mold.

The customer gave positive feedback on the use of the additively manufactured mold inserts, incorporating them into their large-scale production line.

Download Metal AM magazine