H.C. Starck Tantalum and Niobium rebranded to TANIOBIS

April 22, 2020

H.C. Starck Tantalum and Niobium GmbH, Goslar, Germany, will do business under the name TANIOBIS from July 1, 2020. The rebranding follows the company’s purchase by Japan-based JX Nippon Mining & Metals in 2018 from original owners H.C. Starck GmbH.

The company stated that its branches and production sites in Germany (Goslar, Laufenburg), Japan (Tokyo, Mito), Thailand (Map Ta Phut) and the USA (Needham, Massachusetts) will continue to operate as usual under the new name.

H.C. Starck Tantalum and Niobium has sixty years of experience manufacturing materials on the basis of tantalum (Ta) and niobium (Nb), and processes these ores into high-performance powders tailored to customer needs.

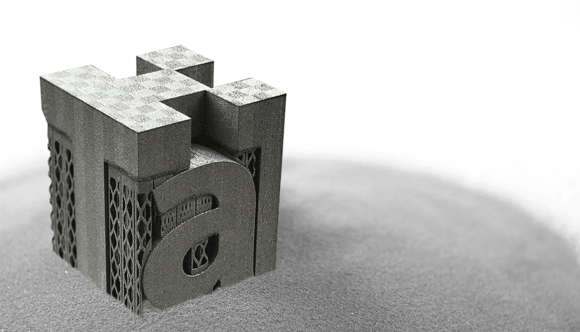

The company announced the launch of its AMtrinsic range of atomised tantalum and niobium powders and alloys designed specifically for metal AM processes in October last year.

“Our new name is a combination of the two key raw materials used in our production operations, tantalum and niobium,” stated Masakazu Kanzaki, the company’s Vice Chairman & CEO. “The characters ‘i’ and ‘s’ at the end stand for ‘innovative solutions’. That’s our personal promise of quality to our customers, underscoring the central role of innovation in our future approach.”

Tantalum and niobium

www.hcstarck-tantalum-niobium.com

(www.TANIOBIS.com from July 2020)