GPAINNOVA America and Xact Metal partner to streamline metal Additive Manufacturing in dental sector

February 13, 2024

GPAINNOVA America, based in Sunrise, Florida, USA, a subsidiary of Spain’s GPAINNOVA, has entered a strategic partnership with Xact Metal, State College, Pennsylvania, USA, to offer a complete solution encompassing design, Additive Manufacturing and finishing processes, leveraging the technologies developed by both companies.

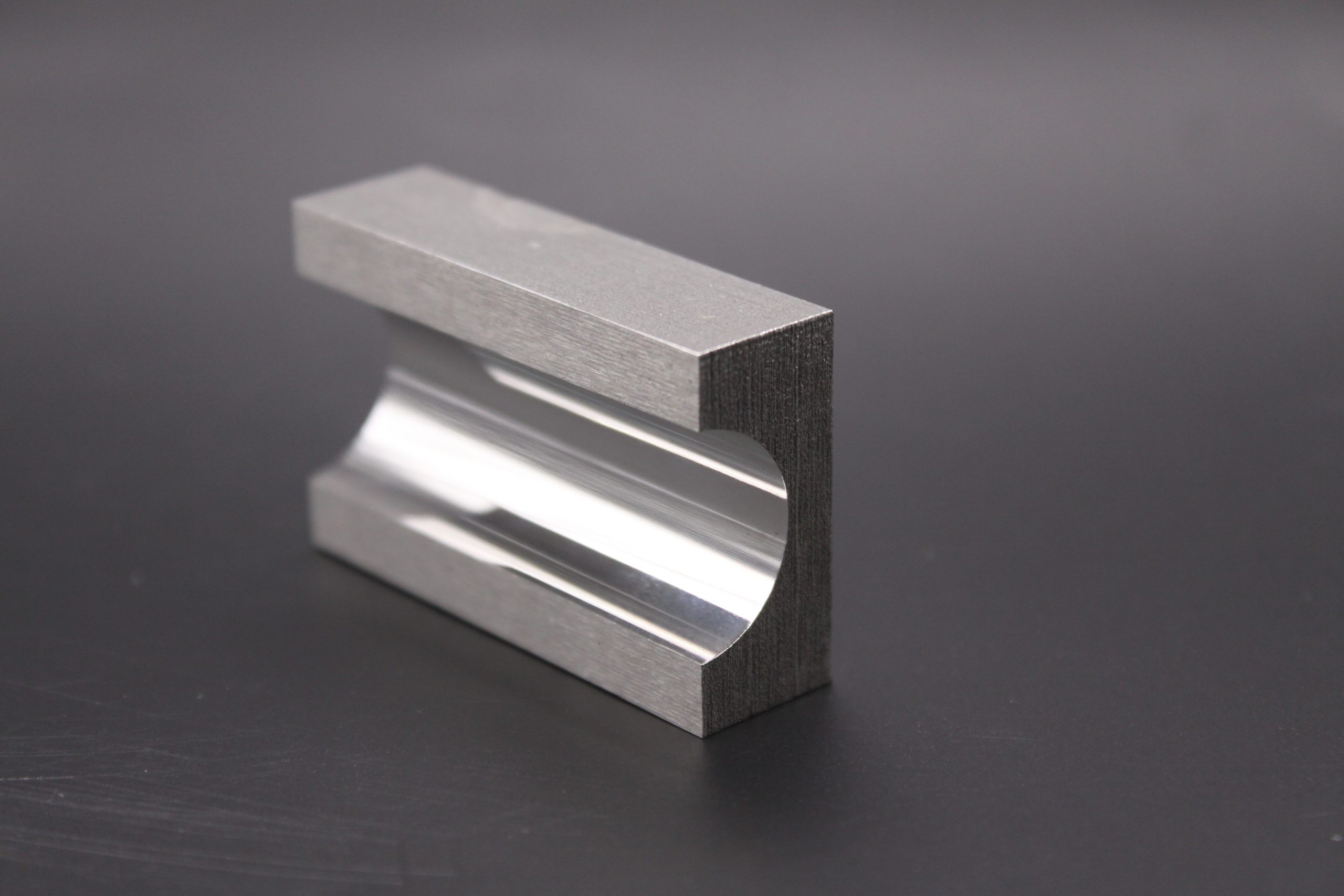

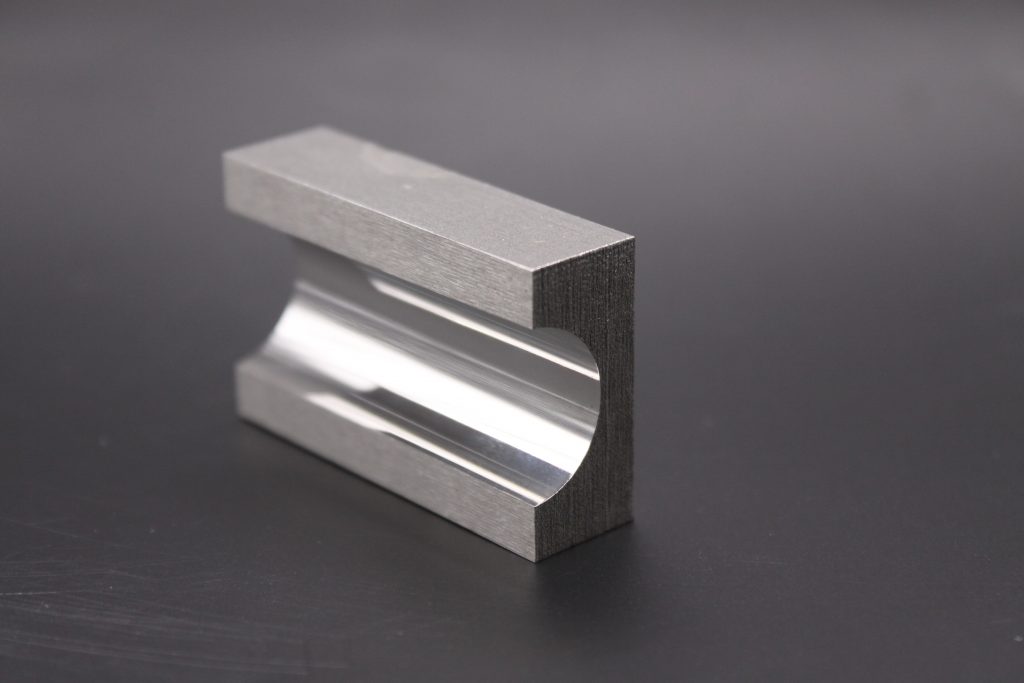

The agreement involves the utilisation of GPAINNOVA’s patented dry electropolishing process, known as the DryLyte Technology, as a post-processing solution for Xact Metal’s metal AM machines. This collaboration aims to streamline the metal AM process, making it more accessible to organisations of all sizes.

Together, the companies will focus on the digitalisation of manual labour in dental laboratories, leading to significant time and cost savings. The process is designed to be less hazardous, providing a safer and more efficient alternative. By incorporating DryLyte finishing technology with the metal AM process, substantial advantages are expected, including a 60-80% reduction in polishing time compared to non-automated methods, faster manufacturing than traditional casting, and a notable reduction in manual labour.

“We are eager to expand our knowledge of how the manufacturing industry integrates the Xact Metal technology into its daily fabrication environment,” stated Jesús Contreras, Business Developer at GPAINNOVA America. “Xact Metal has developed a unique market strategy that creates synergies similar to GPAINNOVA’s; combining our expertise, we can shape the proper perspective for the AM adopters and have a final product to fulfil their needs.”

“We are very excited to begin this partnership with GPAINNOVA to offer a full solution from design to finished part using their patented wet and dry electro-polishing,” shared Xact Metal CEO, Juan Mario Gomez. “It allows the customer to automate the finishing process, reducing the need for manual labour and saving them time.”

Download Metal AM magazine